Now in the Internet era and the information age, network switches are one of the most critical devices that facilitate seamless communication between computers and various peripheral devices. This makes choosing a suitable switch a very important proposition. There are two excellent switches on the market-FS S5860-20SQ and Aruba JL658A. This article will give you the full information and comparisons to help you decide which switch fulfills your need.

FS S5860-20SQ vs Aruba JL658A

Feature

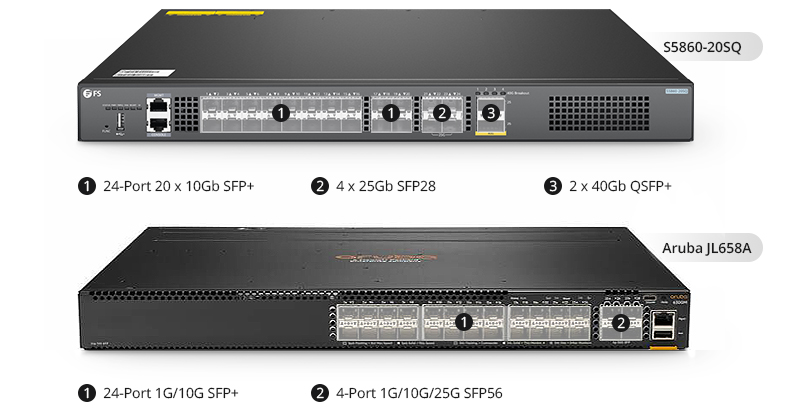

Both FS S5860-20SQ and Aruba JL658A provide preeminent features to meet enterprises’ networking demands. FS S5860-20SQ is a 24-port 10Gb Ethernet layer 3 fully managed pro switch that features 20x 1G/10G downlinks, 4x 10G/25G SFP28, and 2x 40G QSFP+ (can be split into 4x 10G SFP+) uplinks. It supports quality of service (QoS), DHCP, BGP, VRRP, QinQ, etc, offering simplified network management, and the system can recover faults promptly within milliseconds. Aruba JL658A is a 24-port 1G/10G SFP+ and 4-port 1G/10G/25G SFP56 layer 3 switch. It also supports BGP, EVPN, VXLAN, VRF, and OSPF with robust security and quality of service (QoS). Both of them satisfy various port requirements and diverse functional requirements for customers.

Performance

When choosing a switch, performance is a crucial factor, as outstanding performance can lead to better hardware devices and a high-quality network experience. FS S5860-20SQ adopts cutting-edge Broadcom chips to deliver 760 Gbps switching capacity,565 Mpps throughput capacity, and 565 Mpps forwarding rate. And it supports virtual stacking on all optical 10G/25G/40G ports, up to 2 units. FS S5860-20SQ additionally has excellent scalability, supporting IPv4/IPv6 dual-stack for future network expansion. Also, it only has a latency of 1.11μs, providing a more efficient network. Aruba JL658A has an 880 Gbps system switching capacity,660MPPS of system throughput,880Gbps model switching capacity, and 654 Mpps model throughput capacity. It supports stacking for 10 members and the max stacking distance can be up to 10 km with long-range transceivers. It has a latency of 1.99μSec to 2.82μSec. Overall, the performance of Aruba JL658A is better from some perspectives, but the FS agile S5860-20SQ managed switch is also ideal for large-scale campus network aggregations and small to medium-sized network cores, meeting the needs of high-speed, safe, and intelligent business networks.

Safety

In the current information age, network security is extraordinarily significant. FS S5860-20SQ gets secure and simplified access for users and IoT, detected by a professional vulnerability scanning tool (Nessus). It supports diverse functions such as hardware-based IPv6 Access Control Lists (ACLs), hardware CPU protection mechanism, the secure shell (SSH), SNMPv3, DHCP snooping, and network foundation protection policy (NFPP). These can effectively ensure the security and smoothness of your network. On the one hand, they can control network traffic and improve network performance. On the other hand, they can ensure the security and reliability of your data through various security protocols. Aruba JL658A enables secure and simple access for users and IoT as well, coming with an integrated trusted platform module (TPM) for platform integrity. This ensures the boot process started from a trusted combination of Aruba AOS-CX switches. Its access control list (ACL) supports IPv4 and IPv6. Both FS S5860-20SQ and Aruba JL658A supply a secure and thoroughgoing set of functions to guarantee your information and data security.

Reliability

Reliability is a crucial factor in the selection of switches, providing continuous and uninterrupted manipulations. FS S5860-20SQ is equipped with 2 (1+1 Redundancy) hot-swappable power supplies (AC), 2 dual hot-swappable smart fans, and a hardware-level dual-flash chip for superior processing performance and network reliability. 1+1 redundant power supply means that if one power supply fails, the other one can immediately take over its operation. The hot-swappable function allows users to remove and replace components without shutting down the system or cutting off power, which can improve the system’s recovery ability, scalability, and flexibility in emergencies. Aruba JL658A is packed with two fan tray slots and comes with two fan trays (field replaceable and hot-swappable) installed. It also has 2 field-replaceable, hot-swappable power supply slots, supporting AC voltage 100V-240V. In terms of stability, both switches perform equally well, with reliable hardware and software components that ensure consistent and uninterrupted network performance.

Management System

An efficient management system can enormously improve efficiency, reduce service costs, and improve data security. FS S5860-20SQ gets one control center with Airware cloud-based network, allowing users to configure and manage 24/7 from one central location to reduce costs and time. Airware unifies the management of network devices, suitable for industries that have branches, like hotel chains, retail chains, company branches, university branches, etc. On the other side, Aruba JL658A has Aruba Central, a cloud-native microservices architecture, that delivers full-service AI insights, security, and unified infrastructure management for campus, branch, remote, and data center networks. The management systems of both switches are highly intuitive and user-friendly, allowing for easy configuration and monitoring of network settings and performance.

Warranty and Technical Support

Whether to provide reliable warranty policies and professional technical support reflects a company’s consumer service consciousness. FS S5860-20SQ furnishes a 5-year limited warranty against defects in materials or workmanship. Moreover, FS provides a personal account manager, free professional technical support, and 24/7 live customer service to each customer. Once you encounter problems during product installation and use, you can find direct and immediate assistance from an expert. In the same way, Aruba JL658A provides a limited lifetime product warranty coverage varying from different products. It also adds reliable technical assistance so that customers can create a support case online through Aruba Support Portal (ASP) or directly contact technical experts via phone. Both switches come with comprehensive warranty services that provide reliable and timely support in case of any issues or defects.

Cost

For any business, price is a significant element in choosing products. From a comprehensive perspective, the price of FS S5860-20SQ is highly competitive in the market, offering a cost-effective choice for customers. It gives affordability and high performance at the same time. However, for Aruba JL658A, the high quality and brand effect determines its accordingly high price. Although the prices of the two switches are different, based on various consumer needs, they are all worth purchasing.Below is a table that briefly compares the specifications of FS S5860-20SQ and Aruba JL658A.

| Specification | FS S5860-20SQ | Aruba JL658A |

| Ports | 20x 1G/10G SFP+ | 4x 10G/25G SFP28, 2x 40G QSFP+ | 24x 1G/10G SFP+ Ports, 4x 1G/10G/25G1 SFP Ports |

| Switching Capacity | 760 Gbps | 880 Gbps |

| Throughput Capacity | 565 Mpps | 660 Mpps |

| Power Supply | 2 (1+1 Redundancy) Hot-swappable | 2 Field-replaceable Hot-swappable |

| Stack Size | 2 members | 10 members |

| AC/DC Power Supply | AC | AC |

| Frequency | 50-60Hz | 50Hz/60Hz |

| Price | Varies (around US$1,500) | Varies (>US$ 6,000) |

Conclusion

If you are more inclined to purchase cost-effective products, especially when there are budget constraints, then FS S5860-20SQ is a good choice for you. FS S5860-20SQ can satisfy the demands of different campus networks, providing a smooth network experience and reliable hardware facilities. Its hardware dual boot setting makes sure that the switch can be used normally even if a single chip is damaged. At the same time, FS can customize different solutions according to diverse consumer needs, combining S5860-20SQ with other products, and providing professional technical assistance.

If you have more advanced requirements for the switch performance, particularly when you want the switch to achieve higher scalability and higher-level stacking, then Aruba JL658A is a more suitable choice for you. Aruba JL658A has Aruba Virtual Switching Framework (VSF), allowing you to quickly grow your network by high-performance front plane stacking. It also supports enhanced software upgrades and a validated stack deployment.

In summary, you can choose different switches based on practical user needs, including a financial budget, specification requirements, consumption preference, and so on. Both FS S5860-20SQ and Aruba JL658A are surpassing switches for a stable network experience. If possible, you can also consult experts for relevant advice.