Fiber optic cables are designed for long distance and high bandwidth (Gigabit speed) network communications. Bulk fiber optic cables carry communication signals using pulses of light. While relative expensive, these cables are increasingly being used instead of traditional copper cables, because fiber offers more capacity and is less susceptible to electrical interference. So-called Fiber to the Home (FTTH) installations are becoming more common as a way to bring ultra high speed Internet service (100 Mbps and higher) to residences.

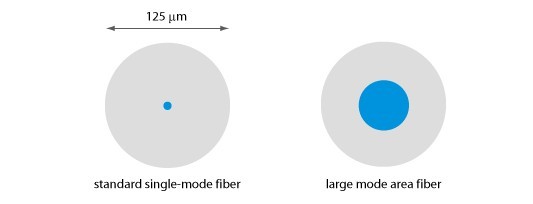

Copper cabling uses electricity to transmit signals from one end to another, bulk fiber optic cable uses light pulses to accomplish the same purpose. The fiber optic cable is made of a transparent glass core surrounded by a mirror like covering called cladding. Light passes through the fiber optic cable, bouncing off the cladding until it reaches the other end of the fiber channel – this is called total internal reflection. As fiber-optics are based entirely on beams of light, they are less susceptible to noise and interference than than other data-transfer mediums such as copper wires or telephone lines. In today’s high speed networks, Graded Index Multimode fiber or Step Index Single mode fiber cable is used to improve light transmission over long distances. Multimode fiber optic cable has a larger core like large core fiber and is typically used in short runs within buildings. Single mode fiber optic cable has a smaller core and is used in long distance runs typically outside between buildings.

While fiber optic cables have so many advantages and widely used in today’s communication. You should take in mind that fiber optic cables are fragile. Fiber cable can be pulled with much greater force than copper wire if you pull it correctly. Just remember following rules:

Do not pull on the fibers. The fiber optic cable manufacturers give you the perfect solution to pulling the cables, they install special strength members, usually Kevlar cutter or a fiberglass rod to pull on. Use it! Any other method may put stress on the fibers and harm them. Most cables cannot be pulled by the jacket. Do not pull on the jacket unless it is specifically approved by the cable manufacturers and you use an approved cable grip.

Do not exceed the maximum pulling load rating. On long runs, use proper lubricants and make sure they are compatible with the cable jacket. On really long runs, pull from the middle out to both ends. If possible, use an automated puller with tension control or at least a breakaway pulling eye.

Do not exceed the cable bend radius. Fiber is stronger than steel when you pull it straight, but it breaks easily when bent too tightly. These will harm the fibers, maybe immediately, maybe not for a few years, but you will harm them and the cable must be removed and thrown away!

Do not twist the cable. Putting a twist in the cable can stress the fibers too. Always roll the cable off the spool instead of spinning it off the spool end. This will put a twist in the cable for every turn on the spool! And always use a swivel pulling eye because pulling tension will cause twisting forces on the cable.

Check the length. Make sure the cable is long enough for the run. It’s not easly or cheap to splice fiber and it needs special protection. Try to make it in one pull, possible up to about 2-3 miles.