The demand for 400G transmission rates by major data centers and telecom carrier continues to grow and cabling solutions are constantly being updated. In order to achieve 400G data rates and save cabling costs, breakthroughs, higher connection density, and simplified network design approaches must be considered, so 400G MTP/MPO cables are becoming more and more common. FS offers MTP/MPO cabling solutions to meet the needs of high-performance 400G networks. This article will describe specific cabling application scenarios.

A Glance at FS 400G MTP/MPO Cables and Transceivers

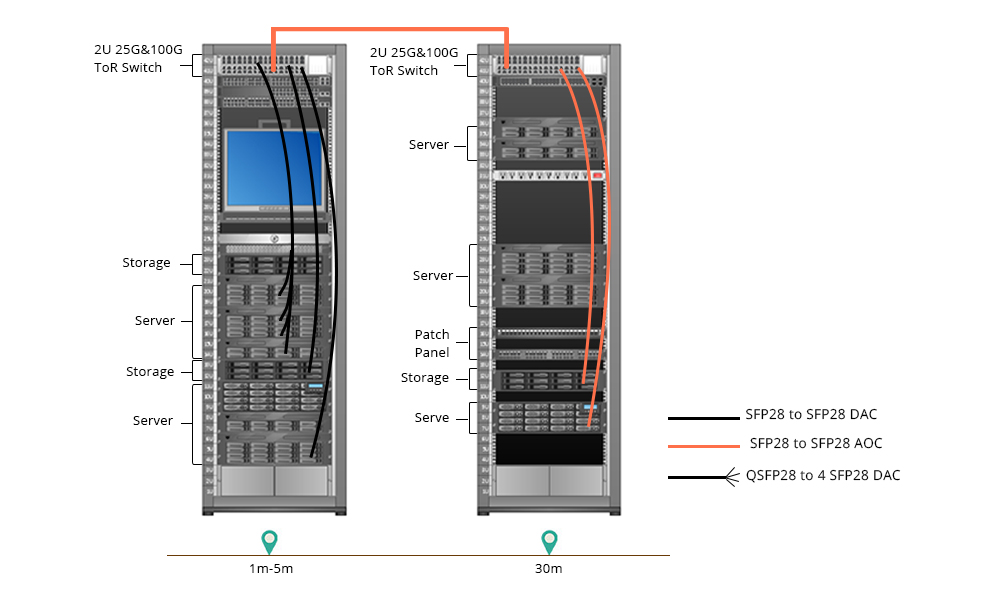

MTP/MPO cables with multi-core connector are used for optical transceiver connection. There are 4 different types of application scenarios for 400G MTP/MPO cables.

Common MTP/MPO patch cables include 8-fiber, 12-core, and 16-core. 8-core or 12-core MTP/MPO single-mode fiber patch cable is usually used to complete the direct connection of two 400G-DR4 optical transceivers. 16-core MTP/MPO fiber patch cable can be used to connect 400G-SR8 optical transceivers to 200G QSFP56 SR4 optical transceivers, and can also be used to connect 400G-8x50G to 400G-4x100G transceivers. The 8-core MTP to 4-core LC duplex fiber patch cable is used to connect the 400G-DR4 optical transceiver with a 100G-DR optical transceiver.

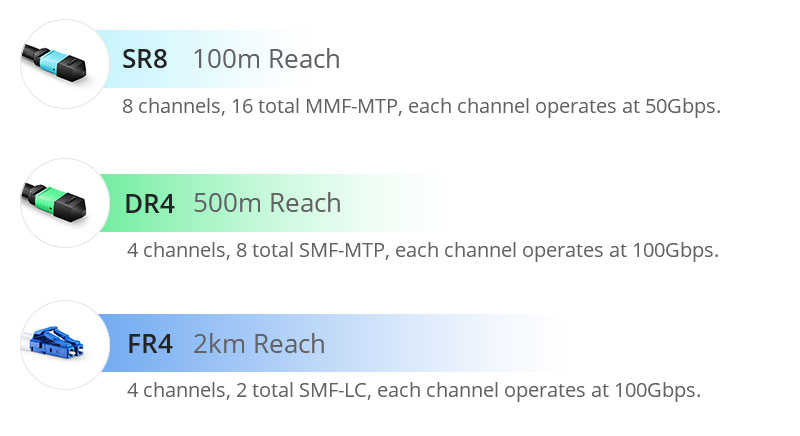

Figure 1: SR8-vs-DR4-vs-DR8

FS 400G MTP/MPO Cabling Solutions for Typical 400G Network Applications

As the network upgrades and data centers migrate to 400G rates, how to transition from existing 50G/100G/200G devices to 400G, here are FS MTP/MPO cabling solutions.

400G-400G Direct Connection

500m span with 8-fiber/12-fiber MTP/MPO cable

400G short and medium distance direct connection usually consists of 8-core/12-core MTP patch cable with 400G-DR4 OSFP/QSFP-DD modules. The term “DR4″—”DR” stands for 500m reach using single-mode fiber and “4” implies there are 4 x 100 Gbps optical channels. Since one optical channel requires two fibers, an 8-fiber or a 12-core MTP/MPO cable can be used for the 400G-DR4 module to achieve direct connection. In the 8-fiber MTP cabling, the fiber utilization is 100%, while in the 12-core MTP cabling, four fibers remain unused. Take 400G QSFP-DD module as an example, the following picture is presenting the MTP cabling for 400G DR4 direct connection.

Figure 2: 400G-400G Direct Connection Scenario 1

| PRODUCTS | DESCRIPTION |

|---|---|

| 400G DR4 QSFP-DD | Generic Compatible 400G DR4 QSFP-DD PAM4 1310nm 500m DOM Transceiver Module |

| MTP®-12 (Female) 12 Fibers OS2 Single Mode | OS2 Single Mode Elite Trunk Cable, 12 Fibers, Type B, Plenum (OFNP) |

100m span with 16-fiber MTP/MPO cable

The 400G-SR8 transceivers require the use of a 16-core MTP cable. The term “SR8” – “SR” stands for a distance of 100 meters using multimode fiber, and “8” implies there exist 8 optical channels with each operating at 50Gbps. In this direct connection, the 16-core MTP cable has 100% fiber utilization. The primary adopters of these 400G-SR8 fiber transceivers are expected to be certain hyperscale cloud service providers in North America and China.

Figure 3: 400G-400G Direct Connection Scenario 2

| PRODUCTS | DESCRIPTION |

|---|---|

| 400GBASE-SR8 QSFP-DD | Generic Compatible 400GBASE-SR8 QSFP-DD PAM4 850nm 100m DOM Transceiver Module |

| MTP®-16 APC (Female) OM4 Cable | OM4 Multimode Elite Trunk Cable, 16 Fibers, Plenum (OFNP), Magenta, 850/1300nm |

400G-2x200G Direct Connection

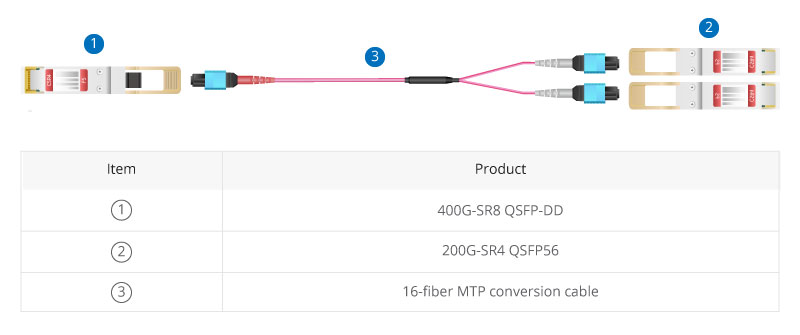

100m span with 16-fiber MTP conversion cable

In the backbone and some more complex metropolitan area networks, the dual-carrier technology (2x200G) will be adopted to compress the channel spacing compared to a single-carrier 400G technology. Extending the transmission distance and improving the spectral efficiency, 400G-2x200G direct connection can help to deploy 400G backbone networks with minimum bandwidth resources.

In this case, 16-core MTP conversion cables terminated with MTP/MPO connectors on both ends are needed. With this type of cable, one 400G OFSP/QSFP-DD module and two 200G QSFP56 modules can be directly connected.

Figure 4: 400G-2x200G Direct Connection Scenario 3

| PRODUCTS | DESCRIPTION |

|---|---|

| 400GBASE-SR8 QSFP-DD | Generic Compatible 400GBASE-SR8 QSFP-DD PAM4 850nm 100m DOM Transceiver Module |

| 200GBASE-SR4 QSFP56 | FS for Mellanox MMA1T00-VS Compatible 200GBASE-SR4 QSFP56 850nm 100m DOM Transceiver Module |

| MTP®-16 APC (Female) OM4 Cable | OM4 Multimode Elite Trunk Cable, 16 Fibers, Plenum (OFNP), Magenta, 850/1300nm |

400G-4x100G Direct Connection

500m span with 8-fiber MTP/MPO trunk cable and 4-LC duplex patch cable

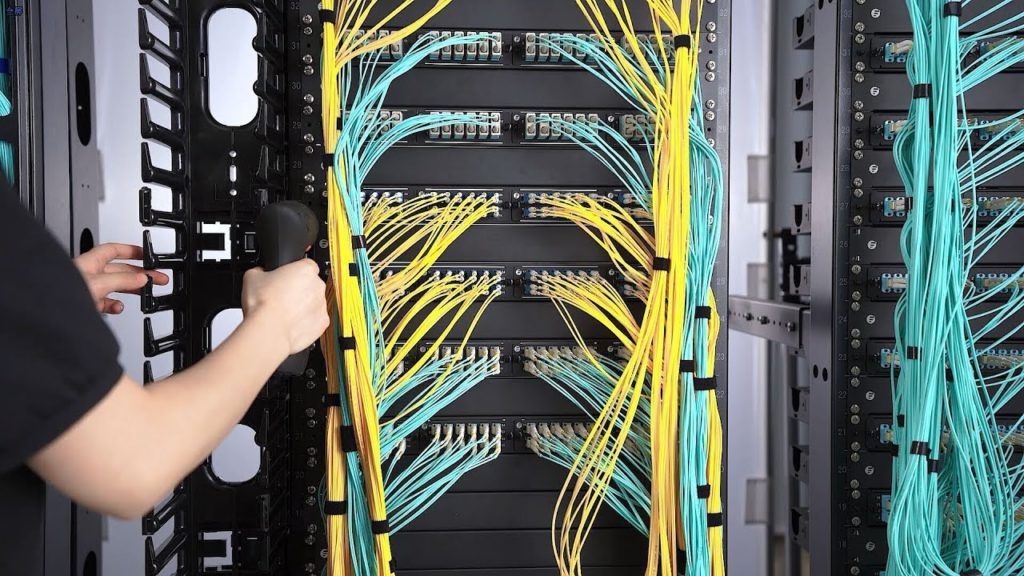

In the 400G to 4x100G migration scenario, an 8-core MTP-LC cassette that packaged in the fiber rackmount enclosure is adopted to realize the transmission from MTP to LC, and then an 8-core MTP/MPO trunk and 4-LC duplex patch cables are used to connect at both ports.

The 400G-4x100G architecture uses four optical modules with 100Gbps wavelengths. However, the current 100G technology is based on a 4x25G design and unable to scale to 400G. 100Gbps per channel can be achieved using PAM4 technology and then aggregated to achieve an overall 400Gbps speed with 4x100G. MTP/MPO cables allow splitting 400G bandwidth into multiple 100G or 40G data streams.

Figure 5: 400G-4x100G Direct Connection Scenario 4

| PRODUCTS | DESCRIPTION |

|---|---|

| 400G DR4 QSFP-DD | Generic Compatible 400G DR4 QSFP-DD PAM4 1310nm 500m DOM Transceiver Module |

| 100GBASE-DR QSFP28 Single Lambda | Generic Compatible 100GBASE-DR QSFP28 Single Lambda 1310nm 500m DOM Transceiver Module |

| MTP® Female to 4 LC UPC Duplex 8 Fibers | MTP Type B Plenum (OFNP) OS2 9/125 Single Mode Elite Breakout Cable 1310/1550nm |

| FHD MTP®-8 Cassette to 4x LC Duplex (Blue) | 8 Fibers OS2 Single Mode, Universal Polarity, MTP® to 4x LC Duplex (Blue), 0.35dB max |

| Customized 8-144 Fibers MTP®-12 | OS2 Single Mode Elite Breakout Cable |

| FHD 144 Fibers (LC) Enclosure | FHD High Density 1U Rack Mount Enclosure Unloaded, Tool-less Removable Top Cover, Holds up to 4x FHD Cassettes or Panels |

400G-8x50G Direct Connection

500m span with 16-fiber MTP conversion cable and LC duplex patch cable

The rapid growth of 400G has contributed in part to the less popular 50G market, and MTP/MPO cables provide the technology to scale 50GbE to accommodate 400G (8x50G) network. For this scenario example, the MTP cassette is in the middle to connect the 16-core MTP conversion cable and the LC duplex patch cords together to realize the 400G-8x50G direct connection. Eight 50G lanes can support the optical link of 40Gbps aggregation via PAN modulation.

Figure 6: 400G-8x50G Direct Connection Scenario 5

| PRODUCTS | DESCRIPTION |

|---|---|

| 400G DR4 QSFP-DD | Generic Compatible 400G DR4 QSFP-DD PAM4 1310nm 500m DOM Transceiver Module |

| MTP®-16 APC (Female) OM4 Cable | OM4 Multimode Elite Trunk Cable, 16 Fibers, Plenum (OFNP), Magenta, 850/1300nm |

| FHD MTP®-24 Cassette to 12x LC Duplex (Aqua) | 24 Fibers OM4 Multimode, Type A, MTP® to 12x LC Duplex (Aqua), 0.35dB max |

| MTP®-16 APC (Female) to 8 LC UPC Duplex Cable | OM4 Multimode Elite Breakout Cable, 16 Fibers, Plenum (OFNP), Magenta,850/1300nm |

| FHD 144 Fibers (LC) Enclosure | FHD High Density 1U Rack Mount Enclosure Unloaded, Tool-less Removable Top Cover, Holds up to 4x FHD Cassettes or Panels |

Scaling to FS 400G MTP/MPO Cabling System for 400G Networks

400G is increasingly becoming ubiquitous in many high-performance and high-density networking environments. 400G MTP/MPO cables have been widely used as cabling solutions for 400G network transmission rates due to their unique cabling simplicity and cost reduction benefits. FS offers a wide range of related 400G MTP/MPO cabling products and solutions to smoothly achieve high-speed data transmission.

Original Source: How FS 400G MTP/MPO Cables Enable Efficient Connectivity