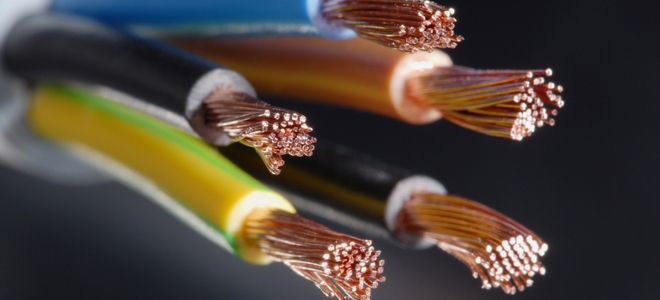

There are many Ethernet network cable wires used for data center applications such as Cat5e, Cat6, Cat6a, and Cat7 cables. The conductor metals adopted by those network patch cables vary in different kinds such as oxygen-free copper wire, pure copper wire, copper clad aluminum wire, and aluminum wire. This article discusses the above network cable wire and compares the differences.

What Is Oxygen-Free Copper Wire?

An oxygen-free copper wire is the highest conductivity copper cable wire that is refined to reduce the amount of oxygen to less than 0.003%, the total impurity content to less than 0.05%, and the purity of copper to more than 99.95%. Thereby, improving the conductivity and oxidation resistance.

What Is Pure Copper Wire?

The pure copper wire has a slightly lower copper content than that of oxygen-free copper wire, which is around 99.5% to 99.95%. The other impurities are some metals such as iron and oxygen. The pure copper wire has excellent conductivity, thermal conductivity, plasticity, and is easy to be pressed.

What Is Copper Clad Aluminum Wire?

The copper clad aluminum wire is an electric conductor composed of an inner aluminum core and an outer copper cladding. Since it contains aluminum, it is significantly lighter and weaker than pure copper wire or oxygen-free copper wire, but stronger than pure aluminum wire. Copper clad aluminum wire is not compliant with UL and TIA standards, both of which require solid or stranded copper wires, but it’s a cheap alternative for category twisted-pair communication cables.

What Is Aluminum Wire?

An aluminum wire is made of pure aluminum. Due to the lightweight nature of aluminum, aluminum wire is quite malleable. However, when compared with copper wire, it has lower electrical and mechanical properties, which is a relatively poor electrical conductor.

Aluminum VS Copper Wire: Which Is the Better Network Cable Wire?

Despite being the best material, copper is a little expensive than aluminum. Thus, people prefer to use aluminum to save money without compromising quality. However, when the aluminum wire warms, it expands, and when it cools, it shrinks. With each gradual warm-cool cycle, the tightness of the wiring decreases, resulting in sparks, even fires. Aluminum wire will also corrode when it encounters certain metal compounds, which increase the resistance to the connection. Thus, aluminum wire requires higher maintenance than copper wire. In contrast, copper has one of the highest electrical conductivity rates among metals. Copper has high tensile strength so it can withstand extreme stress and is more durable. Due to its high elasticity, high durability, low maintenance, and high performance, it is a more stable material than aluminum. So a good manufacturer will use a great deal more copper in the wire to ensure the performance.

Conclusion

Now we know that copper wire outweighs aluminum wire when used in wired networks. The higher the copper content of the network cable wire, the better the conductivity and transmission capacity. However, most of the network cables sold on the market are pure copper wires or copper clad aluminum wires. FS provides oxygen-free copper wires, which outperforms among the peers. These oxygen-free copper wires are 100% pass the Fluke Channel Test with PVC CM jacket material, making them the best choice for you in terms of price and quality. If you’re interested, please visit www.fs.com.

Related Articles:

How to Choose and Buy the Best Ethernet Cable

Quick View of Ethernet Cables Cat5, Cat5e And Cat6

Solid or Stranded Conductor Cable, Which to Choose?