People have really enjoyed the power and the flexibility of fiber optic cabling all around the world. Fiber optic cabling is becoming the fastest, smartest and most flexible way to enable large amounts of digital data to be transmitted and received. These long thin strands of cable have revolutionized the way our phone, television and information systems work. Without these cables, we wouldn’t have high speed broadband internet. Fiber optic cables are inexpensive, flexible and do not take much power to run. These advantages have made them a popular favorite among many communication companies. The only problem is, many people still know little about fiber optic cabling technology.

Here are some fiber optic cabling facts:

Fiber optic cables have a history – The technology surrounding fiber optics has been around since the 1870’s. The first introduction of actual fiber optic cabling started showing up in the 1950’s. This is a technology rooted in solid history.

Fiber optic cables use light – There is no electrical current being passed through fiber optic cabling, only light. Because of this, there is no heat and no heat means no burning and no fire hazards. During normal use, fiber optics are the safest option for data transmission.

Fiber optic cables are fast – Data can be transmitted through fiber optic cabling faster than traditional cabling due to increased capacity. Right now, commercial uses of fiber optic cabling can transmit 10-80 Gigabits per second over just one channel. According to reports, the current record is 15.5 Terabits per second over a distance of 7,000km. To put that into perspective, that’s the equivalent of 10.3 million DSL connections.

Fiber optic cables have many uses – From the traditional use of data transmission, fiber optics have grown in their use. Now, they are used with gun sights, imaging optics, spectroscopy, supply low levels of power, signs, art and even artificial Christmas trees.

Fiber optic cables have various types – Two main types of cables are multi-mode optical fibers and single-mode optical fibers. A multi-mode optical fiber has a larger core (≥ 50 micrometers), allowing less precise, cheaper transmitters and receivers to connect to it as well as cheaper connectors. There is also large core optical fiber(common 100 micrometers or even 400 micrometers). There are also Simplex cable and Duplex cable.

Simplex Cable– There is a single strand of fiber which is surrounded by a Single strand of fiber surrounded by a 900 um buffer after that a layer of Kevlar and lastly the outer jacket. It is generally available in 2mm or 3mm in plenum or riser jacket. Plenum is stronger while riser cable is more flexible.

Duplex Cable– The concurrent operation of a circuit in both directions within data communications is known as full duplex. The system is called half duplex when it is capable of sending only one transmission at a time. Two single strands are attached at the center surrounded by a 900 um buffer, and then comes a Kevlar jacket and finally the outer jacket.

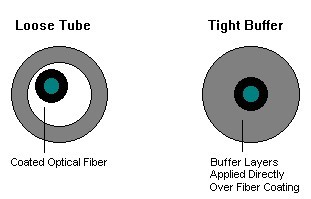

Other types of fiber optic cables are loose tube cable and tight buffered cable, distribution cable, ribbon cable, breakout cable, waterproof cables for moisture environment, etc.