You may familiar with bulk fiber optic cable, but how much do you know the differences between tight buffer fiber and loose tube cable? This article will focus on tight buffer vs loose tube cable.

Tight Buffer vs Loose Tube Cable Design

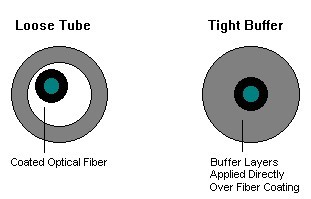

Tight buffer or tight tube cable designs are typically used for ISP applications. Each fiber is coated with a buffer coating, usually with an outside diameter of 900m.

Loose buffer or loose tube cables mean that the fibers are placed loosely within a plastic tube whose inner diameter considerably larger than the fiber itself. Usually 6 to 12 fibers are placed within a single tube. The interior of the plastic tube is usually filled with a gel material that protects the fibers from moisture and physical stresses that may be experienced by the overall cable. Loose buffer designs are used for OSP applications such as underground installations, lashed or self-supporting aerial installations, and other OSP applications.

Advantages of Tight Buffer vs Loose Tube Cable

Each construction has inherent advantages. The loose buffer tube offers lower cable attenuation from microbending in any given fiber, plus a high level of isolation from external forces. Under continuous mechanical stress, the loose tube permits more stable transmission characteristics. The tight buffer construction permits smaller, lighter weight designs for similar fiber configuration, and generally yields a more flexible, crush resistant cable.

The other fiber protection technique, tight buffer, uses a direct extrusion of plastic over the basic fiber coating. Tight buffer constructions are able to withstand much greater crush and impact forces without fiber breakage.

The tight buffer design, however, results in lower isolation for the fiber from the stresses of temperature variation. While relatively more flexible than loose buffer, if the tight buffer is deployed with sharp bends or twists, optical losses are likely to exceed nominal specifications due to microbending.

Tensile Loading

Cable tensile load ratings, also called cable pulling tensions or pulling forces, are specified under short-term and long-term conditions. The short-term condition represents a cable during installation and it is not recommended that this tension is exceeded. The long-term condition represents an installed cable subjected to a permanent load for the life of the cable. Typical loose-tube cable designs have a short-term (during installation) tensile rating of 600 pounds (2700 N) and a long-term (post installation) tensile rating of 200 pounds (890 N).

Conclusion

Tight buffer vs loose tube cable, each has its own advantages and uses. Nowadays there are many big brands fiber optic cable manufacturers provide tight buffer cables and loose tube cables. FS.COM, also offers a wide range of bulk fiber optic cables, including cables from corning and cables for different applications, bulk fiber optic cable can be made in a variety of lengths and configurations to meet your needs. For more details, please visit FS.COM.

Related Articles:

Tight-Buffered Fiber Distribution Cable for Indoor and Outdoor Use

Which Tight Buffered Fiber Distribution Cable Fits Your Application?