When it comes to OSP (outside plant) deployment, many types of fiber optic cables are used for different OSP applications. ADSS (all-dielectric self-supporting) cable is the type that is strong enough to support itself between structures without using conductive metal elements. It is often installed along aerial transmission lines to be a communication medium for electrical utility companies. Both single-mode and multimode fiber can be arranged in ADSS cables. And when using single-mode fibers, the cable can carry the maximum of 144 fibers. But do you know the basic structures of ADSS fiber cable? What are the advantages of using ADSS cable? And how can you prevent ADSS cable from damage? This article will give you all the answers.

Structures of ADSS Cable

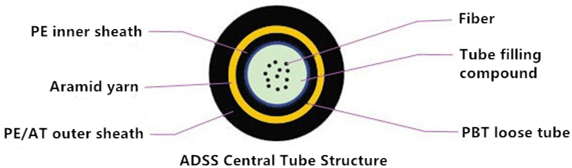

There are generally two kinds of structures for ADSS cable. One is called as central tube structure. From the following picture, the fiber of a certain length is placed in a PBT loose tube filled with water-blocking material. Then it is wrapped with aramid yarn according to the desired tensile strength and extruded with PE or AT sheath. This structure has a smaller diameter and lighter weight. But the fiber length is limited.

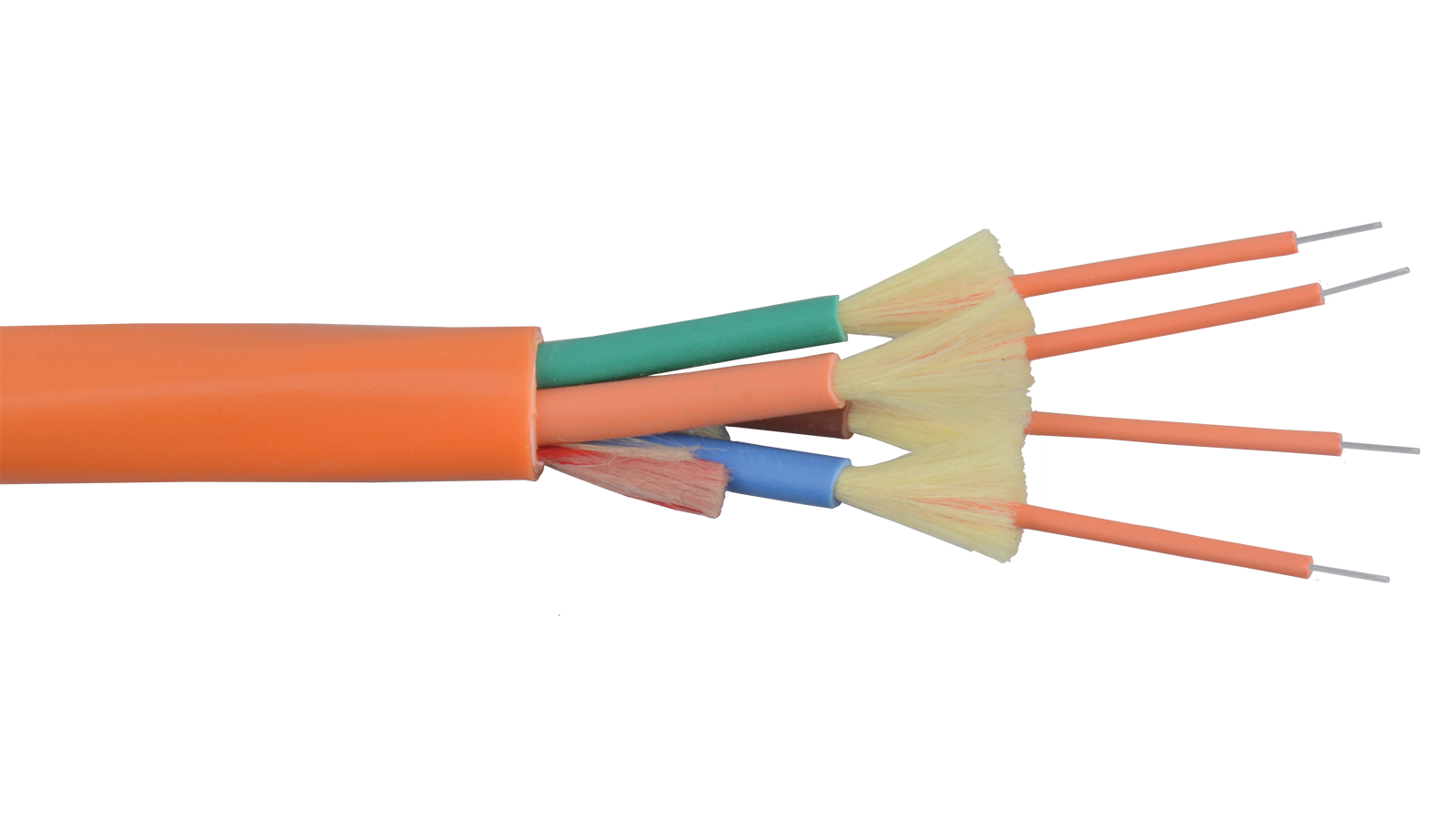

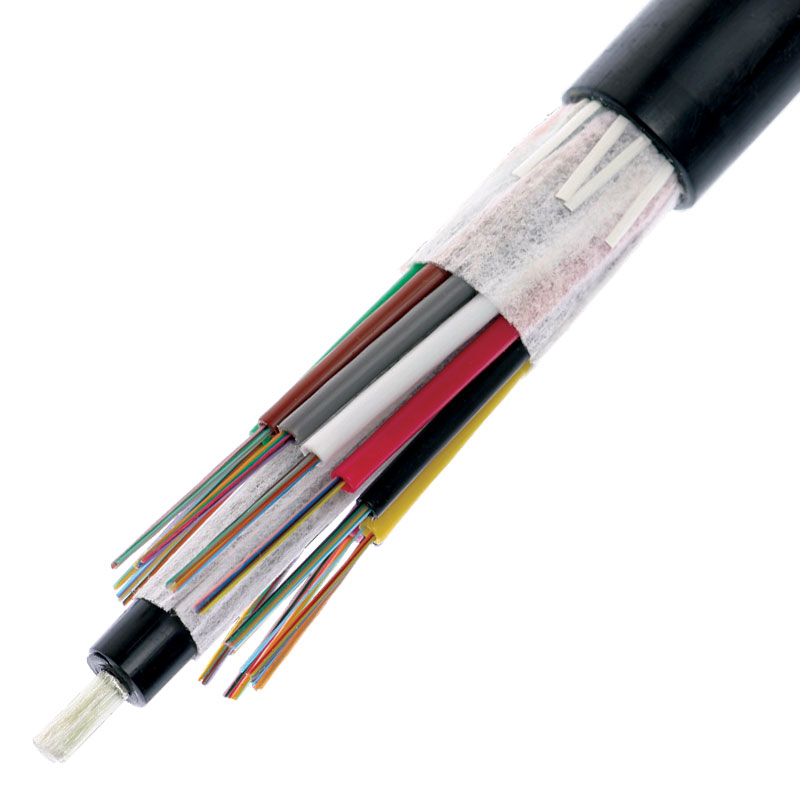

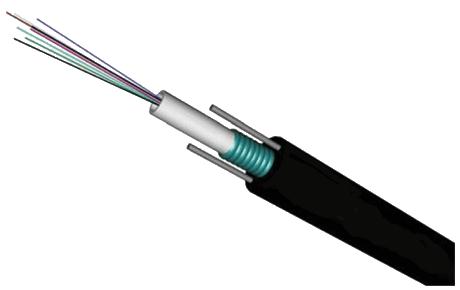

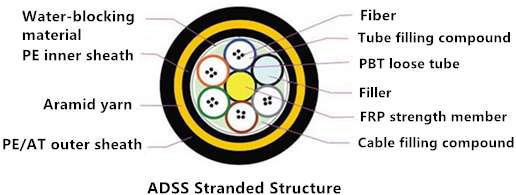

The other type of structure is called as stranded structure. The following picture shows that the fiber loose tubes are surrounding around a central strength member (usually as FRP material). And the rest parts are similar to the central tube structure. This type is able to obtain a longer fiber length. Although the diameter and weight are relatively big, it is better to be deployed for large span applications.

Benefits of ADSS Cable

There are many advantages of using ADSS fiber cable. The overall weight and diameter of the cable are small which is a relief to the towers and poles. And its total transmission range is large enough to reach up to 1200 meters. Using the polyethylene sheath will also protect the cable from corrosive effect. ADSS cable’s non-metallic structure makes it possible to be anti-lightning. And the aramid yarn helps the cable to have good tensile performance and temperature performance under extreme weathers. The maximum lifespan of ADSS fiber cables can even reach up to thirty years.

Precautions for ADSS Cable Damage

- Point 1, since many cables are running through mountainous areas, it is inevitable that the cables will be scratched or bent when come across trees or rocks. Especially for the cable sheath damage, it will greatly harm the service life of cable because the surface can be corroded once exposed to the dust and salty environment. Thus, the cable installation should be under careful examination and monitoring.

- Point 2, due to the partial force during the line construction, common accidents like broken fiber and high loss point can be occurred. Lots of people think it is the problem of cable quality, but actually, it is because of the wrong construction process. Therefore, taking control of the constant tension at a uniform speed during installation is very important.

- Point 3, another common damage is the broken fiber at strain towers. This is because of the wrong operation or partial force on fibers. During the construction, installers must pay attention to the proper angle and pulling direction of fibers to avoid such accidents.

Conclusion

ADSS cable is ideal for installation in distribution as well as transmission environments. It does not need support or messenger wire, a single pass is sufficient for installation which makes it a cost-effective and simple way of setting up fiber optic networks. With careful installation, this type of fiber optic cable can bring much convenience for the proper application.

Related Articles: