Fiber Optic Patch Cord Wikipedia

Patch cord wikipedia defines that Fiber optic patch cord (Fiber Patch Cable or Fiber jumper) are used for linking the equipment and components in the fiber optic network, is a fiber cable that has fiber connectors installed on one or both ends. The fiber optic patch cord types are classfied by the fiber optic connector types. For example, LC fiber optic patch cord means this cable is with LC fiber optic connector. There are PC, UPC, APC type of fiber patch cord types, different from each other because of the polish of fiber connectors. Fiber optic connectors are designed and polished to different shapes to minimize back reflection. This is particularly important in single mode applications. Typical back reflection grades are -30dB, -40dB, -50dB and -60dB. General use of these cable assemblies includes the interconnection of fiber cable systems and optics-to-electronic equipment.

Fiber patch cords are made of 2 major parts: optical connector and fiber optic cable. If the fiber connectors are attached to only one end of a cable, it is known as a fiber optic pigtail. If the fiber connectors are attached to both ends, it is known as a fiber jumper or fiber patch cord.

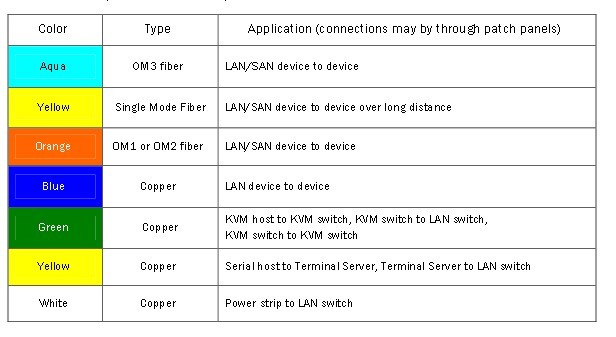

Fiber optic patch cords types are also commonly divided into single mode fiber optic patch cords and multimode patch cord. Here the word “mode” means the transmitting mode of the fiber optic light in the fiber optic cable core. usually, single mode fiber optic patch cable is with 9/125 fiber glass and is yellow jacket color, multimode fiber optic patch cables are with 50/125 or 62.5/125 fiber glass and is orange color.

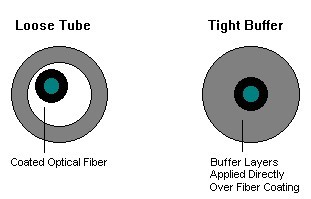

Fiber Cable Structure

1. Simplex fiber optic patch cables: Simplex fiber patch cable has one fiber and one connector on each end.

2. Duplex fiber optic patch cables: Duplex fiber patch cable has two fibers and two connectors on each end. Each fiber is marked “A” or “B” or different colored connector boots are used to mark polarity.

3. Ribbon fan-out cable assembly: For ribbon fan-out cable assembly, one end is ribbon fiber with multi fibers and one ribbon fiber connector such as MTP connector (12 fibers), the other end is multi simplex fiber cables with connectors such as ST, SC, LC, etc.

Below is an example color scheme for patch cables.

Availabilities of Fiber Optic Patch Cord Types:

-Full specifications, FC, SC, ST, LC, MTRJ, E2000, DIN, D4, SMA, etc.

-Simplex and Duplex assemblies available -Singlemode and multimode available

-PC, UPC and APC polishing available

-Hybrid patch cords are available upon request

-Fan-out available (Ribbon type/bundle type)

-Pigtail available -Loopback available

-Customized lengths upon request

Applications of Different Fiber Optic Patch Cord Types:

FTTH application

Premise installations

Data processing networks

Wide Area Networks (WANs)

Telecommunication networks

Industrial, mechanical and military

Conclusion

Based on patch cord wikipedia, we have a good understanding of patch cords. FS.COM provides a comprehensive line of different fiber optic patch cord types, such as OM3 and OM4 multimode fiber cable and OS2 single mode fiber. Want to know more about our fiber patch cord types, please visit FS.COM.

Related Article:

The Advantages and Disadvantages of Optical Fiber

What Kind of Fiber Patch Cord Should I Choose?