Pre-terminated fiber cabling has become a favorable choice for today’s high speed networks in data centers as this technology enables high bandwidth, high port density, easy cable management, future data rates migration and security monitoring. And modular system allows for rapid deployment of high density data center infrastructure as well as improved troubleshooting and reconfiguration during moves, adds and changes. MTP cassette is such a modular module. Usually, it employs configuration of 12 fibers or 24 fibers, containing MTP adapter, LC/SC adapter, MTP-LC or MTP-SC patch cable etc, of which MTP-LC cassette is more widely used. As an assembly of the high density MTP/MPO pre-terminated fiber devices, it is dominant in high-density data centers for its reliable interface, optimized performance and minimized rack space. There are commonly three types of MTP cassettes available in market, including MTP LGX cassette, MTP HD cassette and MTP TAP cassette. This article will introduce the advantages of MTP HD cassette and MTP TAP cassette over the standard MTP LGX cassette.

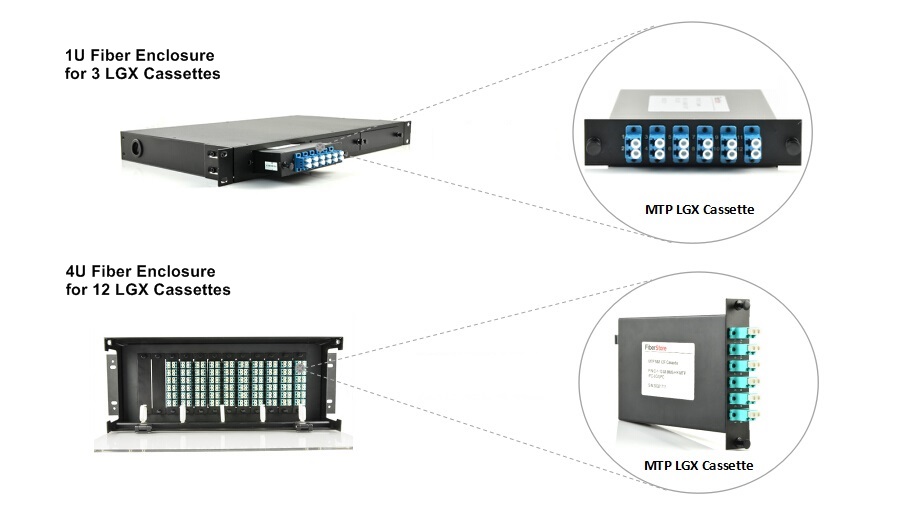

Though the MTP cassette is preferred for its high density, there is still difference in used rack space between MTP LGX cassette and HD cassette. For standard LGX cassette, usually 3pcs of LGX cassette are put inside a 1U19’’ rack, or 12pcs inside a 4U 19’’ rack, as shown in the figure below. However, HD cassette is more optimized for high-density applications than LGX cassette for being more compact in package. 5pcs of HD cassette can be put inside a 1U 19’’ rack. So if the space for a data center is urgent to be saved, MTP HD cassette will be the best selection to help minimize the rack space for the most fiber count.

TAP (traffic access point) is usually added to the network for network monitoring. MTP TAP cassette is an effective device for real-time monitoring in high performance network and high density cabling. TAP cassette integrates TAP functionality into cable patching system. A TAP uses a passive fiber optic splitter to create an exact copy of the light signal passing through it. The optical fiber carrying the signal from a device’s transmit port is connected to the splitter input; the splitter’s live output is connected to the receive port of the downstream device, while a second output carries the copy of the live signal for out-of-band access. A TAP uses two of these splitters, installed on the two fibers supporting both channels of a duplex fiber channel link, to create a complete copy of all traffic between the two devices. And the transmission for the network data will not be affected since there are ports for monitoring and ports for transmission. The MTP TAP cassette can adopt both the package of HD and LGX cassette. The MTP TAP cassette can be easily deployed in network by connecting to the monitoring device and the user device with MTP trunk/breakout cables or LC/SC patch cables. For this hardware tool, TAP cassette is more expensive than the other two cassette types.

This article compares two MTP cassettes with the MTP standard LGX cassette and states the advantages of them. So if space is the primary consideration in high density cabling, MTP HD cassette is a better design choice; if a secure network with high performance is the priority, MTP TAP cassette is recommended to be deployed in the network. For special applications where high density and monitoring are both required, MTP TAP cassette with compact design is the best choice!