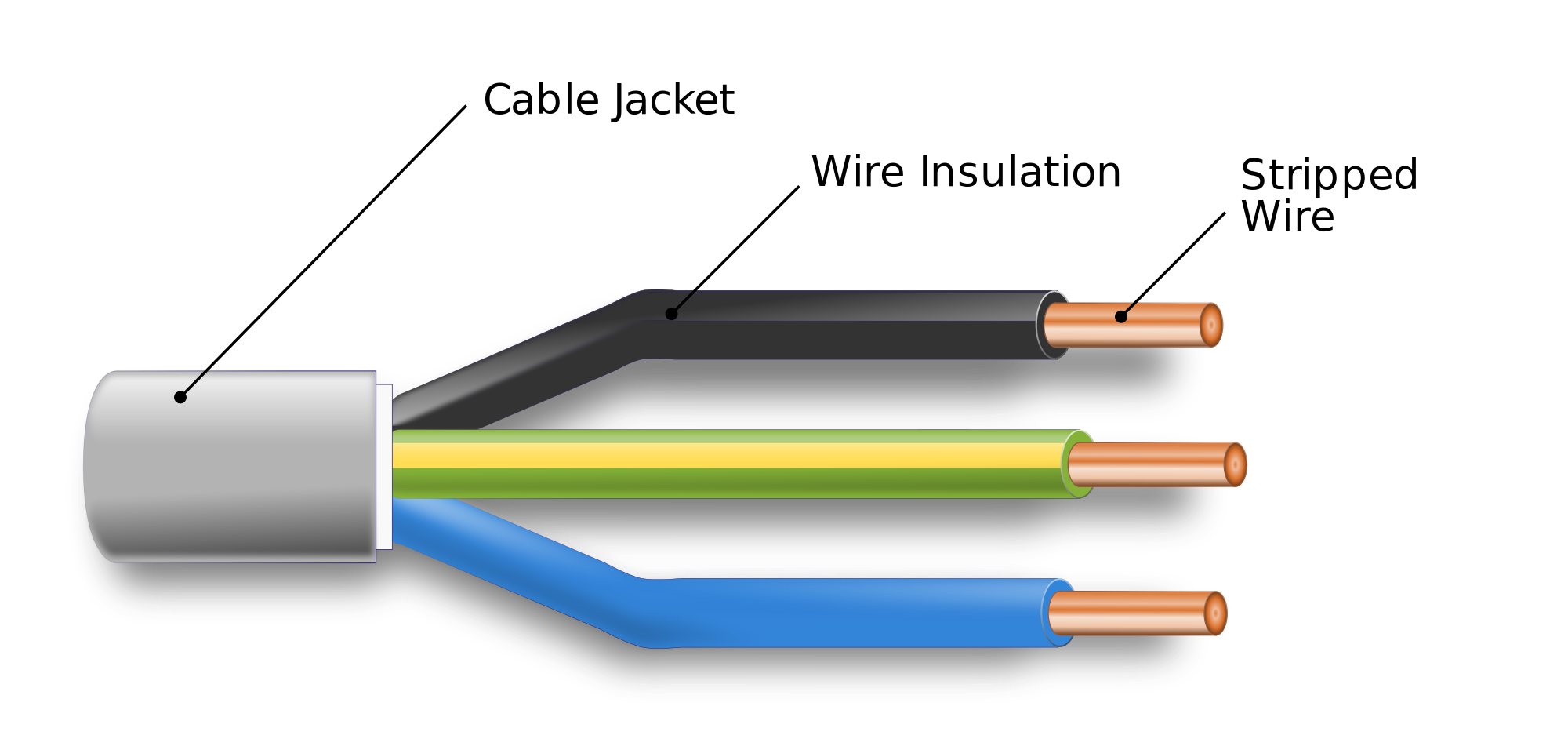

Have you noticed that patch cables are all wrapped in various jackets? These cable jackets are important to serve as the protection for inner cable parts. Different kinds of jackets can influence the applications as well. Knowing the differences in cable jackets will help you make better decisions when choosing cables. Lots of materials can be made as cable jackets to cope with different situations. This article will mainly introduce some common types and analyze their distinctions.

PVC (polyvinyl chloride) is a common jacket type widely used for general patch cables. The low cost and easy manufacture contribute to its popularity around the world. You can find PVC jackets almost everywhere when patch cables are used. PVC material is highly moisture-resistant so that can be perfectly applied to humid environment. But it also has some defects that will limit the service lifespan. For example, PVC material often becomes fragile under direct sunlight and its flexibility is restricted when greater bending is required.

LSZH (low smoke zero halogen) is the material that gives off low toxic and corrosive gas under fire. It greatly ensures the high visibility and low respiratory damage when cables come across open fire or short circuit fault. LSZH cable jacket is typically applied to areas where smoke factor is considered to be the most important, such as aircraft, rail cars, ships, buildings and so on.

OFNP (optical fiber nonconductive plenum) is specified by NFPA (National Fire Protection Association), which has no electrically conductive component inside optical cables. This type of cable jacket can effectively prevent fire and emit low smoke. OFNP cable is the highest fire rating fiber cable and has no replacement. Places including ducts, plenums, and other building airflow areas are suitable for installation.

PUR (polyurethane) cable jacket is the thermoplastic material that is usually used in harsh environment. It provides both mechanical resistance and chemical resistance. Thus, PUR cable can be installed for industrial applications where strong protective coating is demanded. Also, its flexibility makes itself a good material for retractile patch cables in continuously flexing applications. But it is more expensive than the common cable jackets.

PTFE (polytetrafluoroethylene) sheath is a synthetic fluoropolymer material suitable for extreme environment. It is very durable under both high and low temperatures and can not be affected by most oils, fuels and fluids. This kind of cable jacket is widely used in military, aerospace, coaxial, and appliance wiring applications.

Rubber jacket is a good option for portable power applications in outdoor or wet environment. It has better performance than plastic materials in flexibility, high temperature resistance and durability. Other applications like mining submersible pumps, control circuits, motor and associated machinery, construction equipment, etc. are also available.

Silicone is the synthetic rubber with greater flexibility and stronger resistance against extreme temperatures and chemicals. Of course, it does not operate as high temperatures as PTFE. But with the extremely supple characteristic, silicone cable sheath is perfect for applications where lots of wire bending are required. And when it encounters fire, only a small amount of smoke will be produced which is also environmental-friendly.

After reading this article, you may get a general idea about the current cable jacket types and where they should be used. And certainly, if you want to find the most suitable jacket for your project, knowing this information is not far enough. But I hope this article can let you understand the importance of choosing a right cable jacket in your future applications.

Related Articles:

Ethernet Cable Jacket Ratings: CM vs. CMR vs. CMP

Fiber Optic Connector Types, Market, & Installation