Fiber splice tray is designed to provide a place to store the fiber cables and splices and prevent them from becoming damaged or being misplaced. It is also called as splice enclosure or splice organizer. This device does not contain any technical functions, and the design is simple. Also, it has a very low price for people to afford. However, the importance of fiber splice tray for protecting fibers is significant. And the skills needed for using fiber splice tray is not as simple as you think.

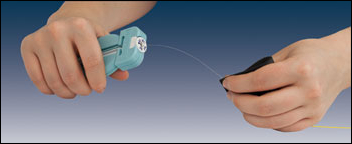

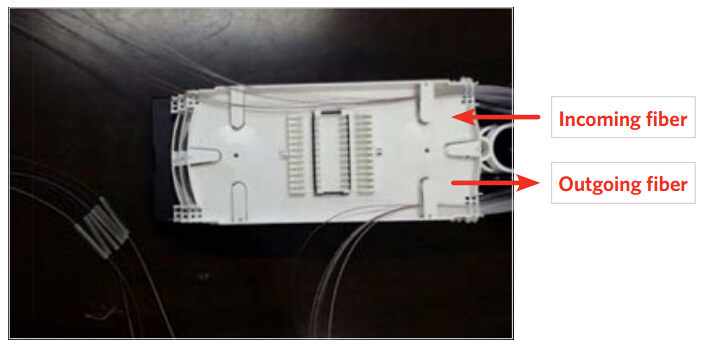

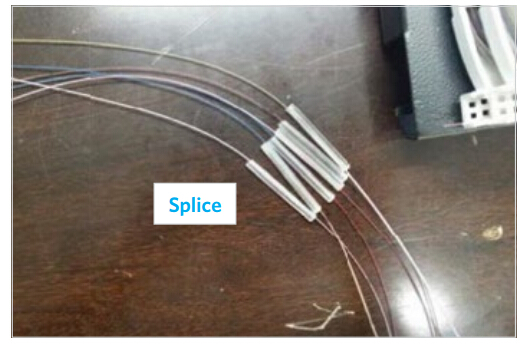

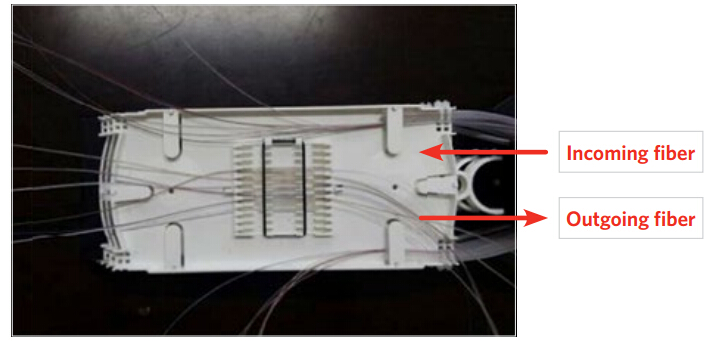

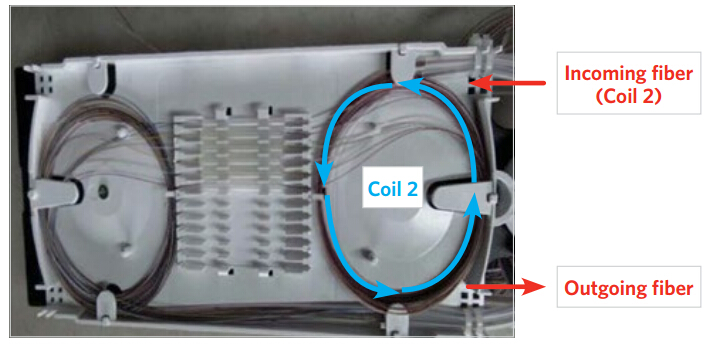

With such a simple structure, you may wonder how the fiber splice tray actually works. Here is the brief introduction of its working function: The incoming cable is brought into the splicing center where the outside jacket of the cable is stripped away. The fibers are then looped completely around the tray and into a splice holder. Different holders are available for different types of splices. The fibers are then spliced onto the outgoing cable if it is an intermediate point or on to pigtails if it is a termination point. These are also looped completely around the tray and then fed out of the tray.

The installation procedures can be divided into five steps:

Step one, route fibers into splice tray using spiral transportation or fiber furcation tubes and secure with cable ties.

Step two, splice fibers per local practice.

Step three, place spliced fibers into the sleeve holders arranged by color code.

Step four, carefully coil the outgoing fiber slack into the tray (coil 1).

Step five, carefully coil incoming fiber slack into the tray (coil 2).

Fiber splice trays are usually placed in the middle of a route where cables are required to be joined or at the termination and patch panel points at the end of the cable runs. Also, splices can be placed in a splice tray which is then placed inside a splice closure for OSP (outside plant) installations or a patch panel box for premises applications. As for indoor application, fiber splice trays are often integrated into patch panels to provide for connections to the fibers.

As a protection for fiber splices, fiber splice tray is no doubt the most cost-effective device. This simple design solves a lot of problems during fiber cables installation. Fiberstore provides different shaped splice trays with different fiber capacities in a competitive price. If you are interested, FS.COM is a good place to go.