Recently I saw many people be in trouble in fiber patch cable management, usually see them stack the cables casually, many people will have the feeling of a mess and always envy other people can do it well, maybe today’s article can give you a lot of help and don’t have to be jealous of other people’s good work.

The optical cord has the possibility to be the weakest link in the fiber optic network, usually in order the finish optimum performance and reliability we must observe true procedures in the administration of the fiber patch cords, the best solution will be the smallest cost and changes or moves. In the fiber patch cable management, the voice connection should be also careful. Well, let’s tell you detailed procedures.

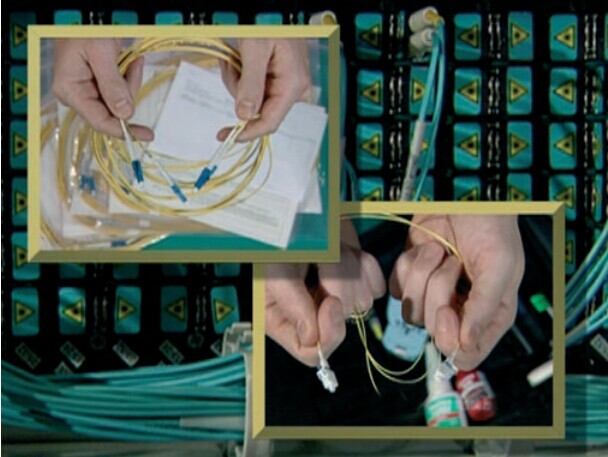

When we receive the request from the administration, be sure that you know the introduction and design of the fiber cabling and you should also know that if you have fiber patch cords that can match to the stalled cabling, the reason is that fiber optic cables have different types and they should be distinguished. Then choose the suitable length of fiber cable. The length depends on its points of connection. It is the shortest one that does not obstruct or interfere with other cords and connectors on the fiber patch panels, avoiding running cords and connectors on the panel. The next step is that tight the fiber patch cords, it will be pulled on connectors and too much slack complicates cable management, making the fiber patch panel more difficult to operate in. At the fiber patch panel, the patch cables equally toward both sides of the vertical cable management channels to prevent overloading one side. Be careful not to mix up cords of different core diameters. Additionally, cords must be of the same or higher bandwidth as the behind-the-wall cabling. Before the patching, there is a point we need to remember, it is cleaning the connector, the cleaning parts include connector ends on patch cords, connector ends on panels, connector ends on network equipment, as for how to clean different types of the fibre optic connector, such as fibre optic sc connector, fibre optic lc connector…We mentioned it in our Fiberstore’s blog if you are interested in it, welcome to visit Fiberstore’s blog. For example, exceeding the bend radius can result in significant additional loss and adverse impact on channel performance. For example, mpo fiber, the minimum bend radius is ten times the core diameter. Take care not to use excessive force during the patching process. This can stress cords and connectors, reducing their performance. If you need to go to force in pulling a cord, something is wrong. If the existing core is the right length, it may be possible to re-use it. If this is the case, remove the cord completely and re-run it in through the cable pathways. This is the only guaranteed way to ensure there are no tangles, kinks or strains in the cord. The final step is to update the documentation of the as-built configuration and close the work order associated with the completed change request.

The above contents are the summary of fiber patch cable management steps, if there are some trouble when you are putting into the practice, welcome to discuss with us, and the related fiber optics that I mentioned in this page, such as various of fiber cables, fiber connectors, fiber adapters even fiber optic patch panel, you all can find from FS.COM.