In order to meet the overwhelming trend of growing bandwidth, different standards for single-mode and multimode fibers are published, and parallel fiber connector (MTP/MPO) is designed to solve the problem of increasing fiber count. Though the fiber types are changing, the use of the parallel connector seems not to be outdated, not only for present 40G and 100G applications, but also for future 200G and 400G. This post will discuss the issue on a new fiber type and the role of parallel fiber in 40GbE and beyond networks.

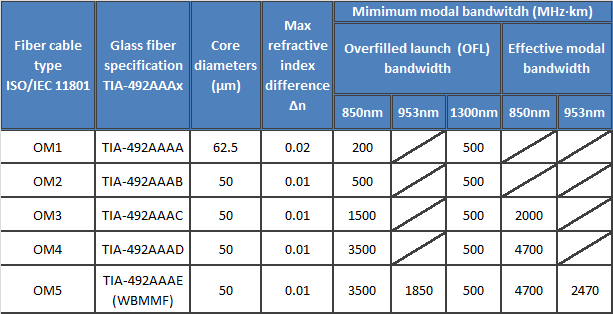

Since the establishment of multimode fiber in the early 1980s, there has been OM1 and OM2, and laser optimized OM3 and OM4 fibers for 10GbE, 40GbE and 100GbE. OM5, the officially designated wideband multimode fiber (WBMMF), is a new fiber medium specified in ANSI/TIA-492AAAE. The channel capacity of multimode fiber has multiplied by using parallel transmission over several fiber strands. In terms of single-mode fiber, there are only OS1 and OS2; and it has been serving for optical communications without much change for a long time. Compared with the constant updates of multimode fiber and considering other factors, some enterprise customers prefer to use single-mode fiber more over the past years and for the foreseeable future. With the coming out of the new OM5 fiber, it seems that multimode fiber might last for a longer time in the future 200G and 400G applications.

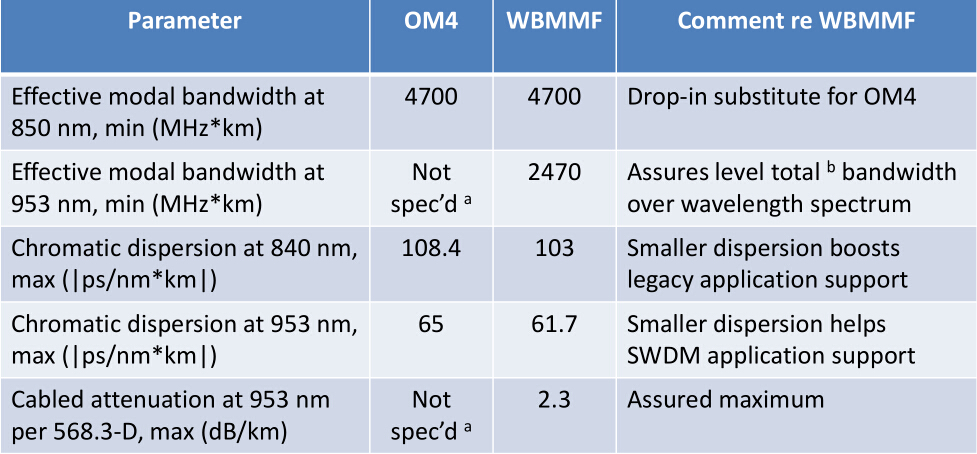

The new fiber medium OM5 is presented as the first laser-optimized MMF that specifies a wider range of wavelengths between 840 and 953 nm to support wavelength division multiplexing (WDM) technology (at least four wavelengths). It is also specified to support legacy applications and emerging short wavelength division multiplexing (SWDM) applications. Although OM5 has been anticipated to be “performance compliant and superior to OM4” based on the following parameters, there are still some arguments on the statement that OM5 is a better solution for data centers.

Figure 1: OM4 and OM5 comparison.

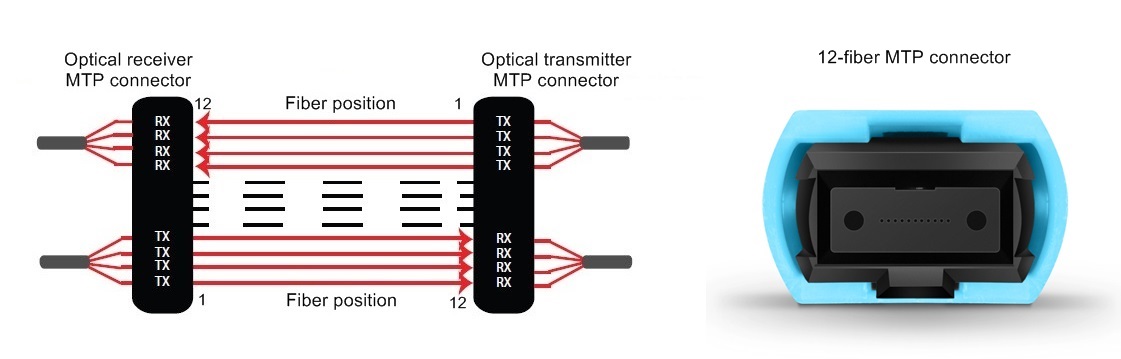

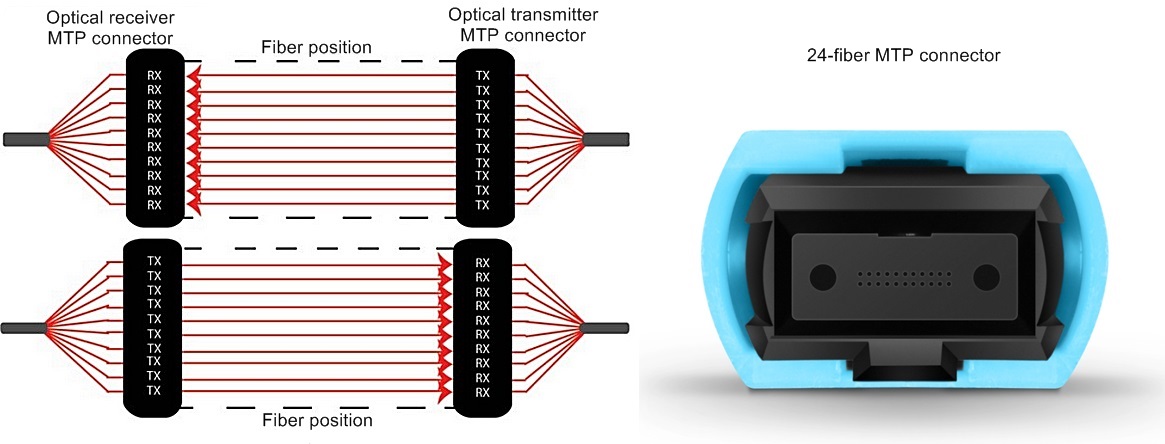

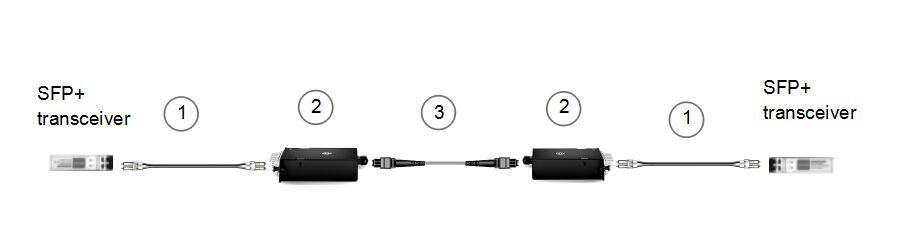

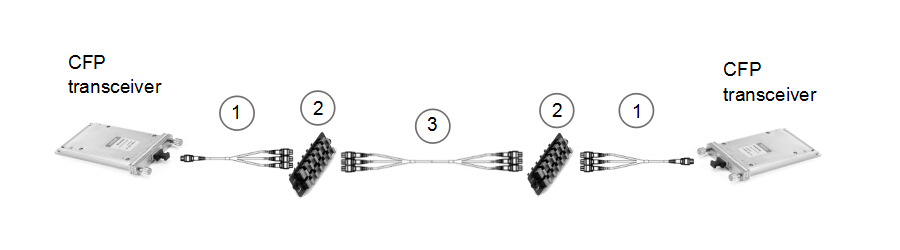

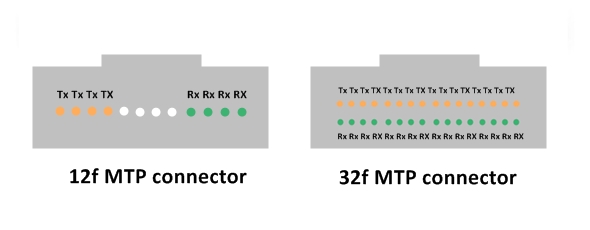

OM5 supporters talk about the problems of present multimode fibers in long-term development. The opinion holds that the future 400GBASE-SR16 which will reuse 100GBASE-SR4 technology specified in IEEE 802.3bs Standard draft, calls for a new 32 fibers 2-row MTP/MPO connector instead of a 12 fibers MTP/MPO connector. It will be hard for current structured cabling that uses MTP-12 to move to MTP-16 requirements.

Figure 2: 12f MTP connector (left) and 32f MTP connector (right).

Figure 2: 12f MTP connector (left) and 32f MTP connector (right).

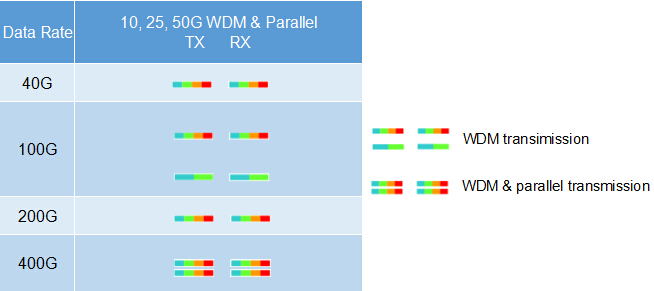

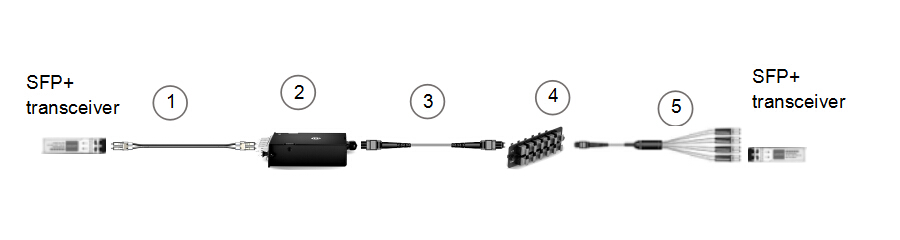

However, the OM5 fiber solution, which can support 4 WDM wavelengths, will enable 4 fiber count reduction in running 40G, 100G and 200G using duplex LC connections. Combined with parallel technology, 400G can also be effectively transmitted over OM5 fibers using only 4 or 8 fibers.

Figure 3: 40G, 100G, 200G, and 400G WDM transmission over OM5 fiber.

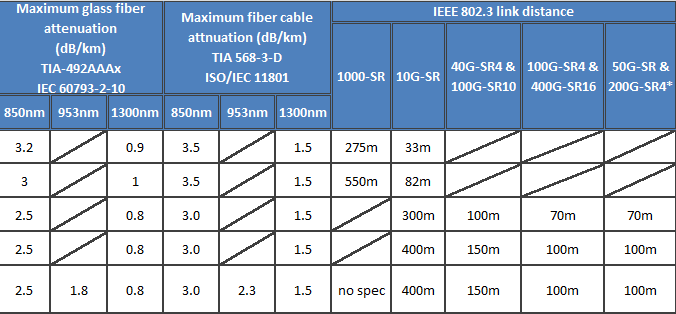

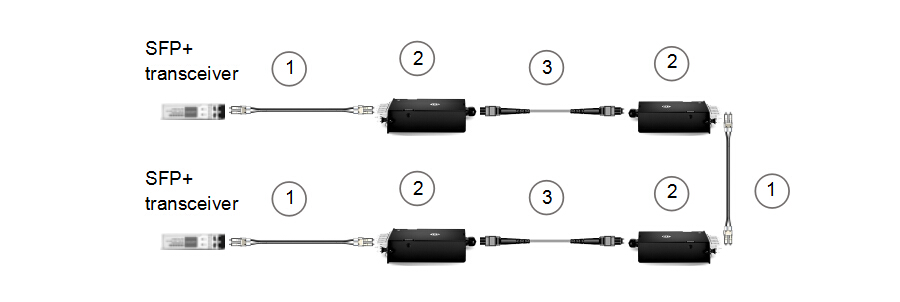

On the other side, some people don’t support the idea that OM5 is a good solution for future 400G network. They argue that OM5 isn’t that optimized than current MMF types. The first reason is that for all the current and future multimode IEEE applications including 40GBASE-SR4, 100GBASE-SR4, 200GBASE-SR4, and 400GBASE-SR16, the maximum allowable reach is the same for OM5 as OM4 cabling.

Figure 4: Multimode fiber standard specifications.

Figure 4 continued.

The second reason is that, even by using SWDM technology, the difference on the reaches for OM4 and OM5 in 40G and 100G is minimal. For 40G-SWDM4, OM4 could support a 400-meter reach and OM5 a 500-meter reach. For 100G-SWDM4, OM4 could support 100 meters and OM5 is only 50 meters more than OM4.

And thirdly, the PAM4 technology can increase the bandwidth of each fiber from 25G to 50-56G, which means we can stick to current 12-fiber and 24-fiber MTP/MPO connectors as cost-effective solutions in the 40G, 100G and beyond applications.

The options for future higher speed transmission are still in discussion, but there is no doubt that no matter we choose to use new OM5 fiber or continue to use single-mode fiber and OM3/OM4 fiber, the “parallel fibers remain essential to support break-out functionality” as stated in WBMMF standardization. It is the fact that parallel fiber solution enables higher density ports via breakout cabling and reduces cost per single-lane channel.