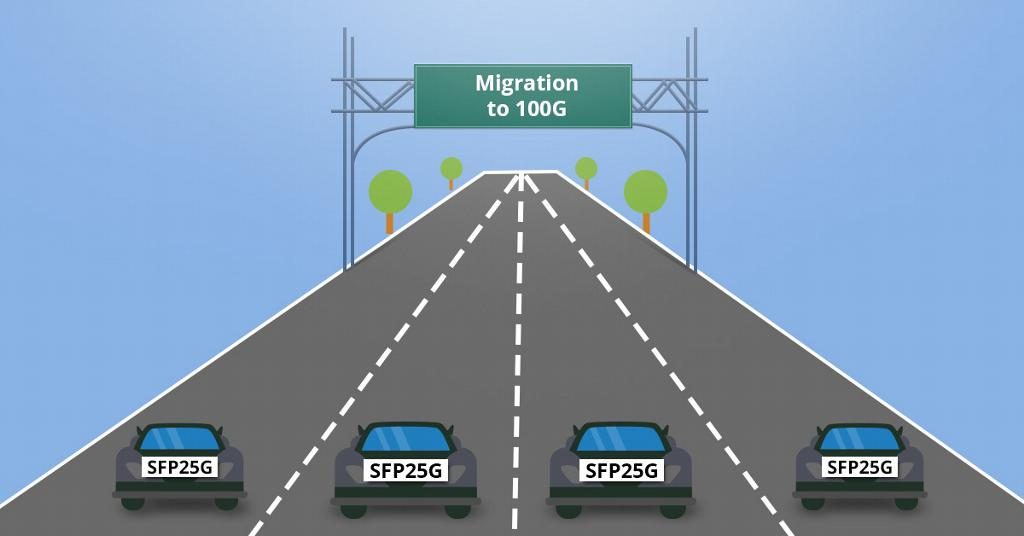

In recent years, the fast growth of data centers leads to increase in global data traffic, which give rise to the need for faster data transmission over a network. 25G Ethernet is the product of that condition. 25G Ethernet is regarded as an incremental update from 10G Ethernet, and it supports 100G Ethernet with single lane at 25Gbps. Due to the booming of 25G, some industry experts claimed that 40G Ethernet is dead, which is biased in some degree. Then 25G vs. 40G Ethernet, which is even better?

Different from 40G and 100G, 25G is a single-lane variant for 25Gbps operation, and that allows a breakout of 100G, which fit the most popular form factors. Based on existing module form factors, such as SFP28 and QSFP28, 25G operations allow for a breakout connection that is configurable as either 25G per lane or the full 100G without changing the port on front of switches, bring more flexibility in the rack and front-panel connections. In addition, with the 25G Ethernet, network operators are no longer forced to use a 40G QSFP port to go from one individual device to another to achieve 100G throughput. The final advantage of 25G is that it can use existing optical plants (depending on what was installed) and increase the bandwidth by 2.5x without changing the physical infrastructure.

As 25G Ethernet is just rising, the interoperability becomes an important factor to ensure wide market adoption and to offer higher speeds for future applications. Besides, compared with 10G 40G and 100G, there aren’t many products of 25G, which limit the development of 25G networks.

40G Ethernet is an Ethernet standard developed by the IEEE 802.3ba Task Force to support sending Ethernet frames at 40 gigabits per second. It also addresses physical layer specifications for communication across back planes, copper cabling, multimode fiber optic cable, and single mode fiber. And 40G Ethernet technology is more mature compared with 25G. In the market, there are various types of products for 40G applications, especially the MPO trunk cable assemblies, cassettes, and QSFP 40G optical modules, which offers the required bandwidth for different applications.

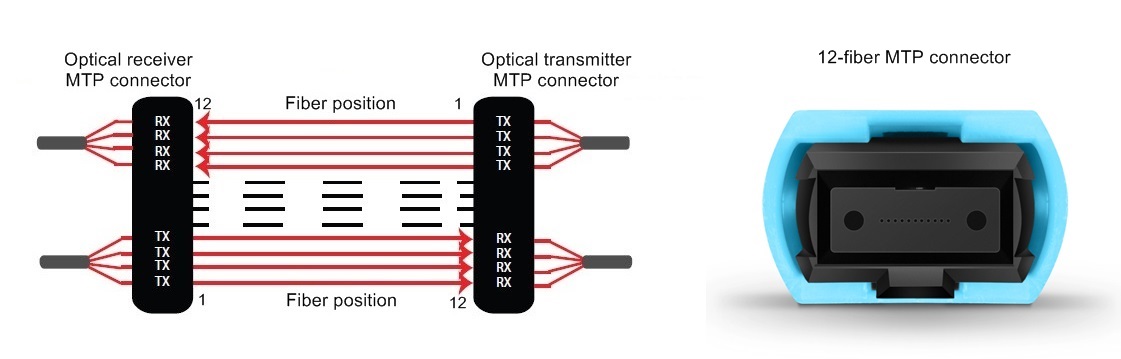

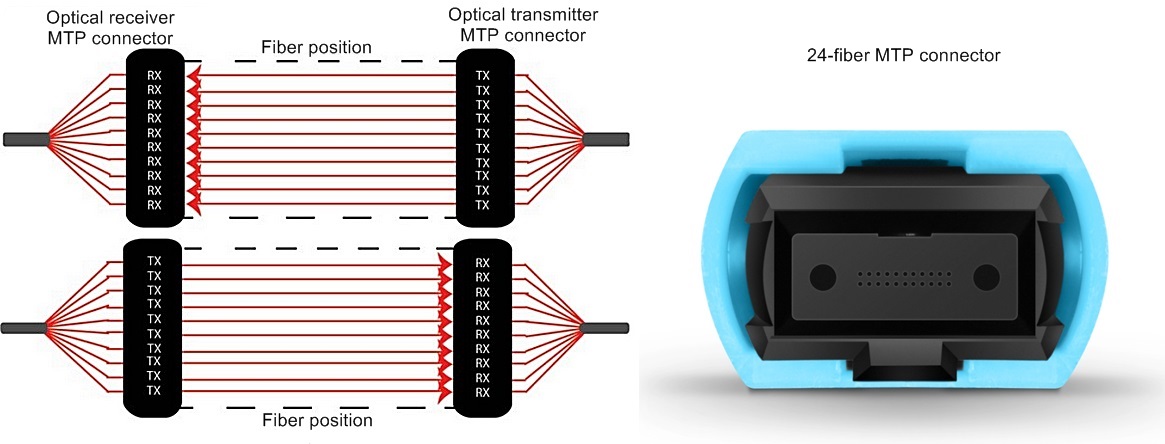

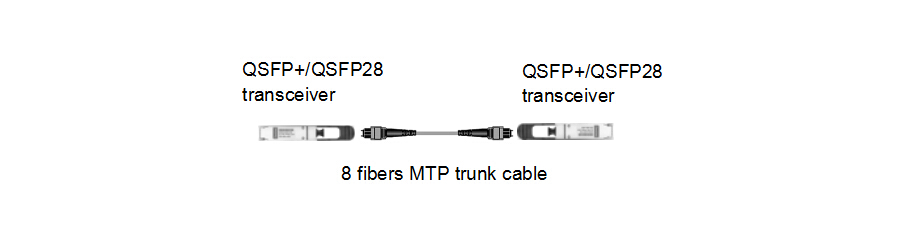

At present, 40G is popular in data centers and no drawbacks found. If we have to say one, the utilization of fibers may be one. As we all know, 12-fiber cabling solution is common in 40G networks. But there are four fibers unused, resulting in fiber waste.

At present, 25G is mainly used for switch-to-server applications. While 40G is for switch-to-switch applications. In other words, no one is using 25G for switch-to-switch links right now. Even the industry giant like Cisco doesn’t offer 25G optical transceiver. But with the fast development of 25G Ethernet, 25G for switch-to-switch application maybe come into reality in the near future.

Switches are important when comparing 25G and 40G Ethernet. Most switches are currently sold, like Cisco 93180YC-EX, Arista 7060CX-32S support both 10G and 25G, and the price is not higher than older 10G products with full backward compatibility. For example, each SFP28 port supports 1G, 10G or 25G, and each QSFP28 port supports 10G, 25G, 40G, 50G or 100G.

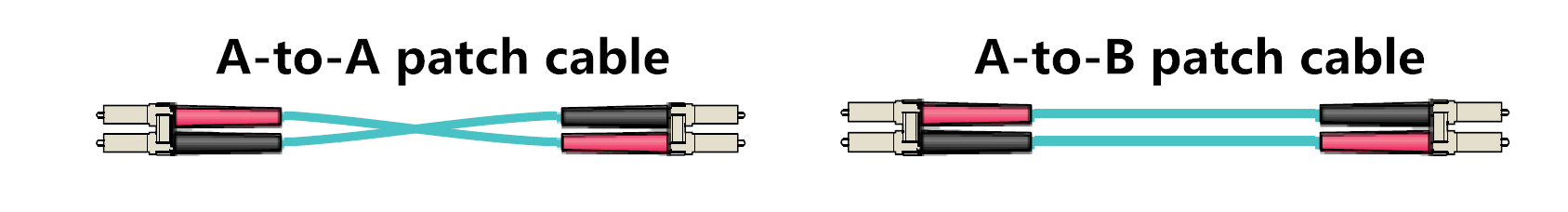

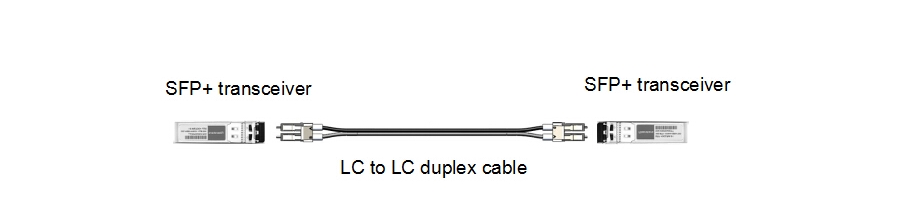

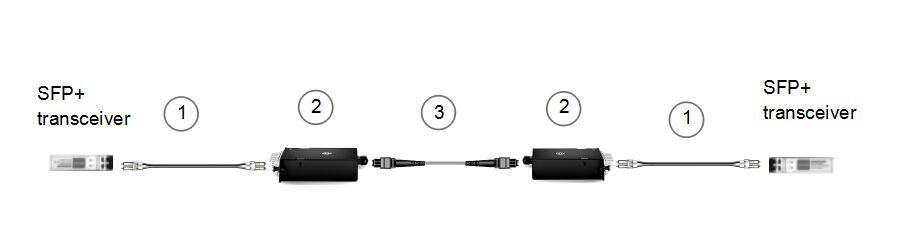

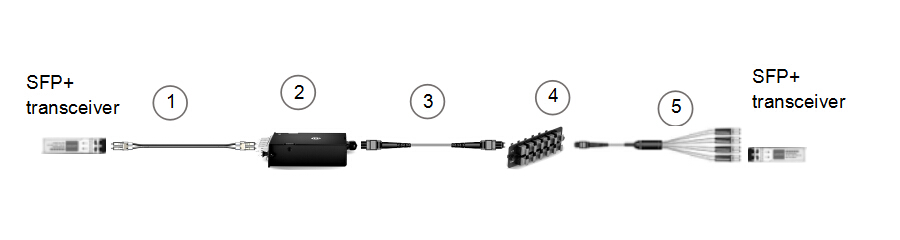

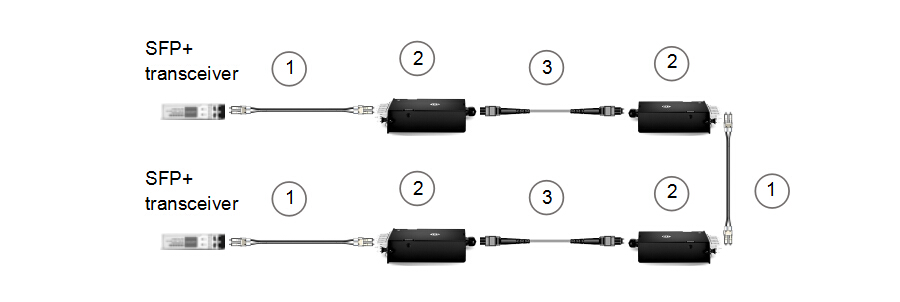

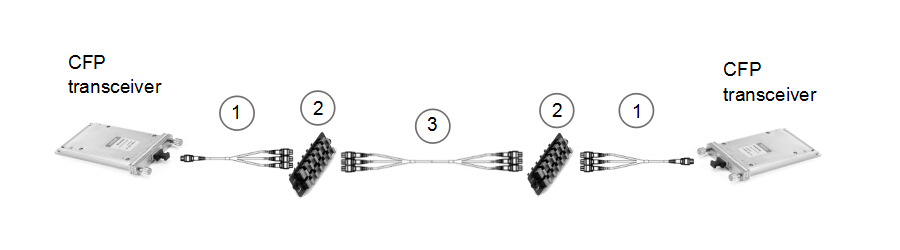

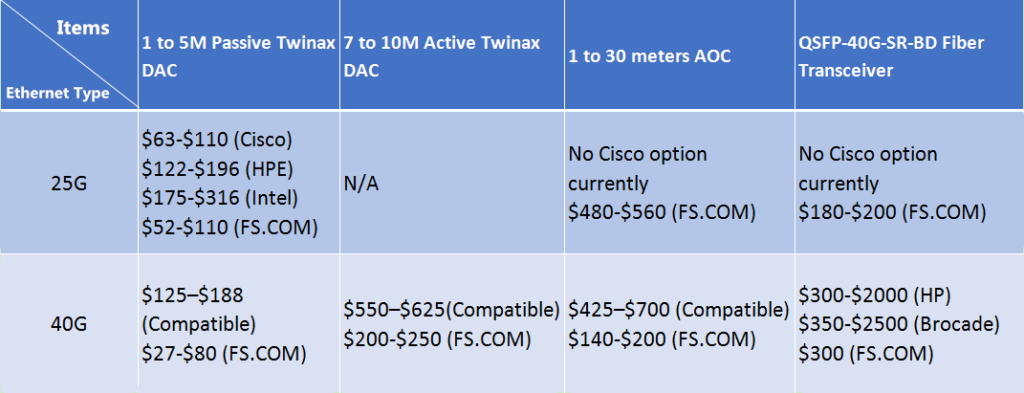

Cabling options determine how far the two types of Ethernet go. It’s a big mistake to ignore cabling. In the market, there are several types of cabling options, and there are some big swings in price. Here is a simple comparison.

From the comparison above, we can draw a conclusion that 25G Ethernet can be used for data centers, but it doesn’t mean 40G is dead. Even though 25G Ethernet seems to have a brilliant future, under present conditions, 40G is a safe choice due to its mature market adoption. Perhaps in a few years, 25G connectivity will be a cheaper alternative.

Related articles:

Taking an In-depth Look at 25G SFP28

25G SFP28 Cable: The Most Economical Option for ToR Server Connection