When testing the transmission equipment, fiber optic loopback device is often used as the testing tool. It is known as the routing of electronic signals, digital data streams, or flows of items back to their source without intentional processing or modification. Fiber optic loopback is widely used for various applications. In terms of telecommunication, loopback is a hardware or software method to feed a received signal or data back to the sender. It is very useful for solving physical connection problems. In this article, the author will especially emphasize the using of loopback in fiber optic communication. Hope it can provide some help for your application!

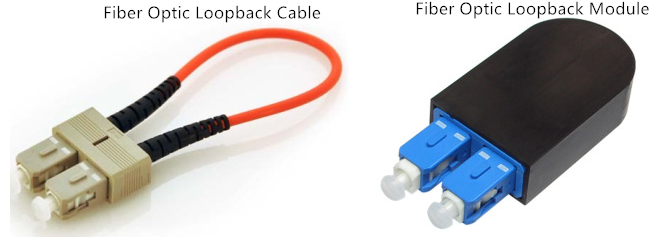

So, what is exactly the fiber optic loopback? By diagnosing the problems of optical equipment, fiber optic loopback provides an easy way to test the performance of the optical network devices. Generally, fiber optic loopback cable and fiber optic loopback module are both fiber optic loopbacks. Fiber optic loopback cable is the traditional fiber optic loopback with a visible cable. It is equipped with two fiber optic connectors on each end of the cable. When sticking the connectors together, the cable will shape like a loop. As for fiber optic loopback module, the biggest difference is that it has a enclosure to protect the inside cable. And the looped space is reduced for an easier usage and economic package.

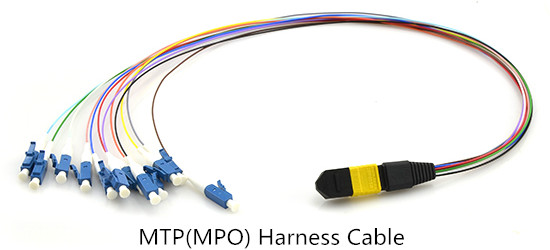

You may find that loopback also has different types of optical connectors and fibers. Categorized by connectors, fiber optic loopback has SC, LC, MTRJ, E2000 types, etc. LC fiber optic loopback complies with the RJ-45 style interface. Having a low insertion loss, low back reflection and high precision alignment, LC fiber optic loopback is widely used all over the world. Another frequently used type is SC fiber optic loopback. Its connector is compliant to IEC, TIA/EIA, NTT and JIS specifications. Now it is the most popular loopback with low cost but high performance. In addition, to separate by fiber types, single-mode loopback (9/125) and multimode loopback (50/125, 62.5/125) are deployed for the application.

Typically, a loopback test is a test in which a signal is sent from a communication device and looped back to the device as a way to determine whether it is functioning well or as a way to troubleshoot a defective node in the network. As for fiber optic loopback testing, optical loopbacks are used to verify the operational reliability of the device. Using fiber optic loopback cable or fiber optic loopback module for data transmission, the signal emitted by the device is looped from the transmit (Tx) end of an active component back to the receive (Rx) end of the same component.

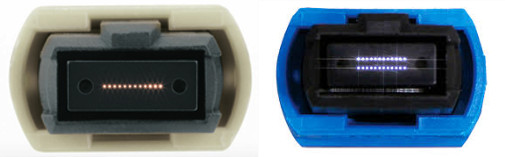

When it comes to practical application, fiber optic loopback test is often employed for checking fiber optic transceivers. Since transceiver has two ports for receiving and transmitting the light signal, it is necessary to test the ports to see whether they are still under operation. Thus, fiber optic loopback test is the most convenient way for transceiver maintenance. The testing process is by routing the laser signal from the transmitter port back to the receiver port. Then the transmitted pattern is compared with the received pattern to make sure they are identical and have no error.

In a word, fiber optic loopback is basically a patch cord used for fiber optic loopback testing. Similar to other cables, it also has multiple classifications of fiber types, connector types for different needs. The deployment of fiber optic loopback components has greatly saved the trouble for device checking. There is no doubt that using fiber optic loopback is an effective method in fiber optic communication.

Related Article: Which Fiber Loopback Should I Use for My Transceiver?

Related Article: What Is Loopback Cable And How to Use It?

-1.jpg)