You hear about fiber optic cables whenever people talk about telephone system, cable TV system or the Internet. They are also used in medical imaging and mechanical engineering inspection nowadays. How much do you know the basic information of cables? For example, what a 9/125/250µm cable mean. In this article, we will show you some cable basics.

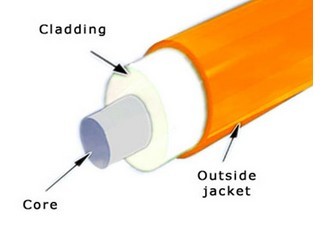

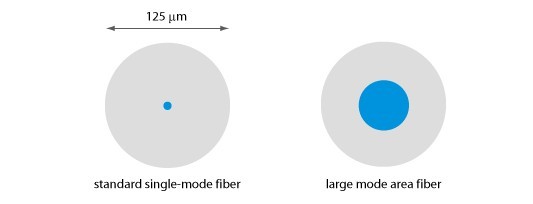

The size of the optical fiber is commonly referred to by the outer diameter of its core, cladding and coating. Example: 50/125/250µm indicates a fiber with a core of 50 microns, cladding of 125 microns, and a coating of 250 microns. The coating is always removed when joining or connecting fibers. A micron (µm) is equal to one-millionth of a meter. 25 microns are equal to 0.0025 cm. (A sheet of paper is approximately 25 microns thick).

Cables can be identified by the type of paths that the light rays, or modes, travel within the fiber core. Also according used in different environments, there are outdoor cable, waterproof cables, lszh cable, submarine optical cable, etc.

These cables are small in size, and used for short, dry conduit runs, riser and plenum applications. The fibers are double buffered and can be directly terminated, but because their fibers are not individually reinforced, these cables need to be broken out with a “breakout box” or terminated inside a patch panel or junction box.

They are suitable for conduit runs, riser and plenum applications. Because each fiber is individually reinforced, this design allows for quick termination to connectors and does not require patch panels or boxes. Breakout cable can be more economical where fiber count isn’t too large and distances too long, because is requires so much less labor to terminate.

These cables are composed of several fibers together inside a small plastic tube, which are in turn wound around a central strength member and jacketed, providing a small, high fiber count cable. This type of cable is ideal for outside temperatures and high moisture conditions(waterproof cables also do good jod in moisture conditions), as it made with the loose tubes filled with gel or water absorbent powder to prevent harm to the fibers from water. It can be used in conduits, strung overhead or buried directly into the ground.

This cable offers the highest packing density, since all the fibers are laid out in rows, typically of 12 fibers, and laid on top of each other. This way 144 fibers only has a cross section of about 1/4 inch or 6mm! Some cable designs use a “slotted core” with up to 6 of these 144 fiber ribbon assemblies for 864 fibers in one cable! Since it’s outside plant cable, it’s gel-filled for water blocking.

Used for rodent protection in direct burial if required. This cable is non-gel filled and can also be used in aerial applications. The armor can be removed leaving the inner cable suitable for any indoor/outdoor use. (Temperature rating -40ºC to +85ºC)

Indoor/Outdoor cables combine the flame resistance and safety features of an indoor riser or plenum cable with the durability that is critical for OSP use. The result is a unique, dual-purpose cable that can save time and money by allowing OSP applications to flow seamlessly indoors, using a single cable and no splices.

Aerial cables are for outside installation on poles. They can be lashed to a messenger or another cable (common in CATV) or have metal or aramid strength members to make them self supporting.

These cables combine specialty optical fiber with cabling construction that make installation or deployment easier and/or protect the fibers for long-term use in harsh environments.

Even more types of cables are available and also many brands cables from different manufacturers are available. Corning is one of the outstanding fiber optic cable manufacturers, who invented the first commercially viable low-loss optical fiber in 1970. Today Corning remains the global market leader in the industry, the corning fiber optic cable is recognized for their excellence and innovation.