Compared with copper wire, optical fiber’s dominant advantage is the overwhelming information carrying capability, and its high bandwidth and low attenuation easily offset its higher cost. FTTx (fiber to the x) architecture is a typical example of substituting copper by fiber in high data rate traffic. FTTx is a generic term for any broadband network architecture that uses optical fiber to replace all or part of the usual metal local loop used for the last mile telecommunications. The x can be substituted by another letter determined by the delivery topologies that are categorized according to where the fiber terminates. What are the termination places and which letter can be used to substitute x? This article will introduce some FTTx terms.

Different FTTx Architectures

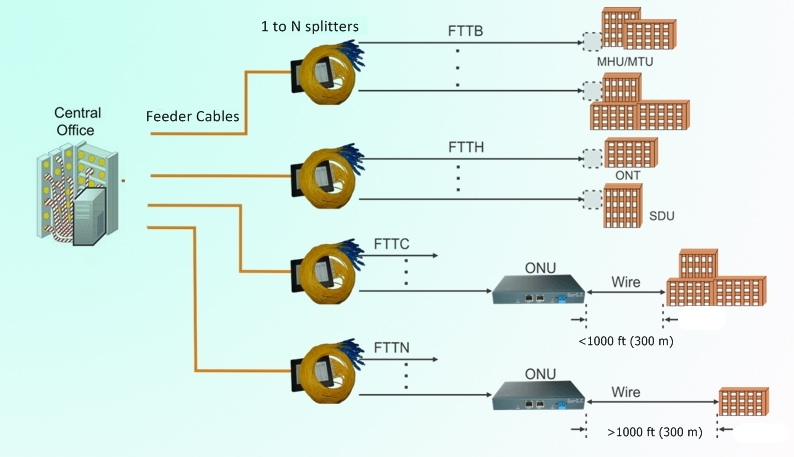

Usually the FTTx items that we are going to introduce are used loosely, as some relate to each other, or just acronyms. Generally the FTTx configurations may fall into two groups: fiber laid all the way to the premises/home/building (FTTP/FTTH/FTTB) and fiber laid to the cabinet/node (FTTC/FTTN), with copper wires completing the connection. Also there are some other FTTx topologies, such as FTTZ (z for zone) and FTTD (d for desktop). The following figure shows simplified schema for four most common FTTx architectures.

FTTP: fiber-to-the-premises, is a loosely used term, which can encompass both FTTH and FTTB or sometimes is used a particular fiber network that includes both homes and businesses. It depends on how the context is used and specific location of where the fiber terminates. FTTP can offer higher bandwidth than any other broadband services, so operators usually use this technology to provide triple-play services.

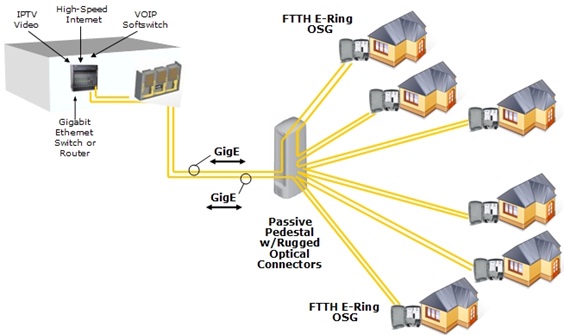

FTTH: as indicated by the name fiber-to-the-home, fiber from the central office reaches the boundary of the living space, such as a box on the outside wall of a home. Once at the subscriber’s living or working space, the signal may be conveyed throughout the space using any means, such as twisted pair, coaxial pair, wireless, power line communication, or optical fiber. Passive optical networks (PONs) and point-to-point Ethernet are architectures that deliver triple play services over FTTH networks directly from a operator’s central office.

FTTB: fiber-to-the-building, -business, or -basement, is very similar to a FTTH. It is a form of fiber-optic communication delivery that necessarily applies only to those properties that contain multiple living or working spaces. The optical fiber terminates before actually reaching the subscribers’ living or working place itself, but does extend to the property containing that living or working place. The signal is conveyed the final distance using any non-optical means, including twisted pair, coaxial pair, wireless, power line communication. FTTB deployment will be the typical for MDU’s and MTU’s (multi-dwelling units and multi-tenant units).

FTTC: fiber-to-the curb or -cabinet, is a telecommunication system where fiber optic cables run directly to a platform near homes or any business environment and serves several customers. Each of these customers has a connection to this platform via coaxial cable or twisted pair. The term “curb” is an abstraction and just as easily means a pole-mounted device or communications closet or shed. Typically any system terminating fiber within 1000 ft (300 m) of the customer premises equipment would be described as FTTC. A perfect deployment example of FTTC is a DLC/NGDLC (digital loop carrier) which provides phone service.

FTTN: fiber-to-the-node or -neighborhood, sometimes identifies and sometimes distinguishes from FTTC. The optical fiber terminates in a cabinet which may be as much as a few miles from the customer premises. Customers typically connect to this cabinet using traditional coaxial cable or twisted pair wiring. The area served by the cabinet is usually less than one mile in radius and can contain several hundred customers. As mentioned before, if the cabinet serves an area of less than 1000 ft (300 m) in radius, the architecture is typically called FTTC/FTTK.

Features of FTTx in LAN Application

Different from a traditional fiber optic network that would be used in local area network (LAN) application, in most FTTx applications, only one optical fiber is used to pass data in two directions. This is very different from the LAN application where the transmit optical fiber sends data in one direction while the receive optical fiber sends data in the other direction. In a LAN application, data transmission over two optical fibers can be simultaneous. However, in an FTTx single optical fiber application, full-duplex operation is typically not possible. Usually half-duplex operation takes place, i.e., part of the time the optical fiber is carrying a signal in one direction and the rest of the time, it is carrying a signal in the other direction. Thus multiple wavelengths are typically used in FTTx systems. The downstream laser is always a different wavelength from the upstream laser. A longer wavelength is used for the former one, such as 1480nm or 1550nm (or both) and typically 1310nm is for the latter one.

Summary

FTTx networks have been acknowledged to be the best choice for phone companies, cities, utilities and commercial service providers to upgrade subscriber connection. Fiber optic cables can carry data at high speeds over long distance while copper cables cannot. The data rate connection is usually limited by the termination equipment rather than the fiber itself, permitting substantial speed improvements by equipment upgrades before the fiber itself must be upgraded. FTTx architecture is being more widely deployed in network applications with its reasonable cost and unlimited performance. FS.COM provides a wide range of FTTx PON components, such as cable distribution and termination accessories, network interface device, PON splitters, etc. For more information you may visit our site or contact sales@fs.com.