Since the late 1970s, various connectors and termination methods have been brought to market. Now in the common case, cables are terminated in two ways: use connectors to make two fibers jointed or to connect the fiber to other network gears; use splices to make a permanent joint between two fibers. And for the former method, you may have little confusions to deal with it. So today this paper will teach you how to terminate by taking an example of fiber optic cable using epoxy.

First and foremost, use a proper fiber stripper to carefully slide the jacket off of the fiber to a bare fiber. When you are doing this, be careful that try to avoid breaking the fragile glass fiber. After that, mix the epoxy resin and hardener together and load it into a syringe (If you use the pre-loaded epoxy syringes that are premixed and kept frozen until use, then you don’t do that). And next you must inject the epoxy from the syringe directly into the connector ferrule.

Once you have well prepared the epoxy for your connector, you can insert the fiber cable gently into the terminus inside the connector wall and make the bare fiber core stick out about a half an inch from the front of the ferrule. In the case that your cable is jacketed, you may need a crimping tool, such as Sunkit Modular Crimping Tool, to secure the connector to the jacket and strength the cables. Usually two crimp tools would be perfect to this operation.

Next, you can just wait the epoxy to cure. During this process, in order to make sure the end of the fiber is not damaged while curing, you should place the connected end in a curing holder. And when this is done, just place the cable and curing holder into a curing oven. But you may worry about “wicking” while curing with a conventional oven. All you have to do to avoid that is to make the end face down, which can ensure the epoxy does not come out of the back side of the connector and compromise the strength member of the cable. Remember: your epoxy curing must in accurate times and temperatures.

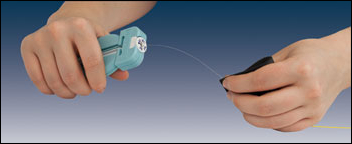

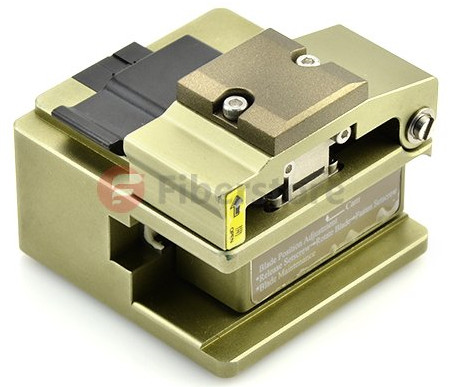

After the epoxy cured sufficiently, fiber cleaver tools will be in use to cleave the excess protruding fiber core so that it could make the fiber close as much as possible to the ferrule tip in case of fiber twisting. Once cleaved, you have to dispose of the fiber clipping. There is a point you should think highly of that you must use a regular piece of tape to retain your fiber debris, or they will easily end up in your skin or even in your eyes or respiratory system.

When you finished the fiber cleaved work, you could need fiber polishing tool to remove the excess epoxy from the ferrule tip and buff out any imperfections on the surface of the fiber. A smooth fiber surface can help to reduce the loss of the light. Last, if you have done all the above work, you may move on to the cleaning of the ferrule and fiber tip. After that, the whole termination procedure is done.

If you want to terminate your fiber optic cables by hands, you can follow the above steps. But before you get down to it, you must prepare the tools first that I have mentioned in this paper. All these tools can be found in Fiberstore with good quality and low price. In addition, Fiberstore also can provide the termination tool kits that may be helpful to you. For more details, you could visit www.fs.com.

Article source: http://www.chinacablesbuy.com/how-to-terminate-fiber-optic-cables.html